Safety bollards cover a wide range of uses in a variety of environments. Every type of parking bollard offers efficient service, from those that address common parking lot pain points to those that protect assets and enhance safety.

The Bollard Shop will offer a wide range of security solutions from parking bollards to removable bollards. At aotons.com we supply our customers with security equipment in the form of premium parking barriers that have been used successfully in businesses, shopping centers, and public spaces across Australia.

Parking problems can be solved with bollards in a variety of commercial, corporate, and residential settings. Since many businesses are concerned with security and safety, Safety bollards are common in parking lots and curbsides. This article will guide you through what safety bollards are, how they are made, and how to use them. Wondering which safety bollards will fit your needs? Please read on to learn more.

1. What is A Safety Bollard?

Safety bollards are used to create a protective boundary around buildings or to provide security. A safety bollard guides traffic and marks boundaries when it is installed. In general, they serve primarily as visual aids. They come in a variety of shapes, and styles, and serve as architectural elements to adorn or visually stand out. Vehicles and pedestrians are also protected by safety bollards.

They are installed to prevent vehicle intrusion, thereby protecting people and property. As security posts, they can also incorporate decorative elements or be chosen to complement the landscaping. First and foremost, however, the main purpose of safety bollards in these situations is impact resistance.

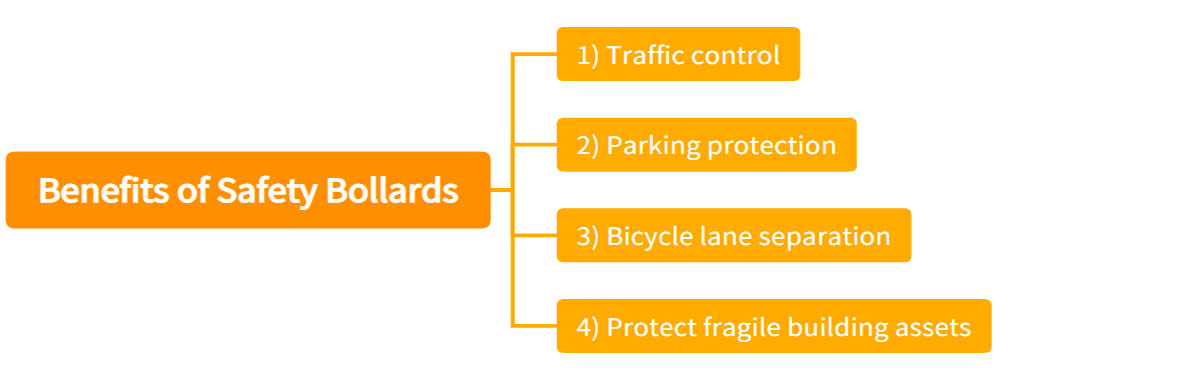

2. Benefits of Safety Bollards

Safety bollards are often used to create a barrier or increase safety around a property, thereby protecting property assets to ensure minimal damage to those assets from passing vehicles.

Safety bollards are also often used as a traffic control measure to direct or restrict vehicles or to encourage or discourage the use of parking spaces. They are also often used in “shared areas” to differentiate between different types of traffic – eg. Vehicles and bicycles, and pedestrian traffic.

1) Traffic control

Traffic bollards allow pedestrian traffic while maintaining clear sightlines and directing traffic to specific areas. They either restrict access to restricted areas such as bike lanes, public squares, and traffic islands, or they direct traffic by demarcating roads.

2) Parking protection

Safety bollards are used to monitor parking space allocation. For example, securing individual parking spaces for specific drivers. This is a very common problem in residential apartment buildings and mixed-use commercial and residential buildings. In these cases, parking bollards address pressure from residents to ensure their parking spaces are reserved for them.

They increase the certainty of parking space availability and increase driver satisfaction. They can be used for parking space protection for individual car owners, for shared parking spaces between fleet drivers, reserved for disabled drivers, or to protect EV charging bays

3) Bicycle lane separation

Separated bike lanes protect cyclists and reduce stress for drivers. In contrast, fragile separators often break on impact, leaving cyclists vulnerable. It can be difficult for emergency vehicles to reach the curb when there are hard boundaries.

4) Protect fragile building assets

Safety bollards are often placed in front of vulnerable assets in buildings to reduce the risk of accidents. Brightly colored security bollards will be installed as barrier posts around vulnerable gas or water meters. They are also often used to protect fragile or historic architectural features close to traffic.

Decorative bollards are often used in areas reserved for pedestrians or parks to protect wildlife or plants from harm. The message from the safety bollards is clear: be aware of restricted access areas where people walk, drive, or cross the road. It is also used to prevent intruders from entering loading docks, garages, bike lanes, streetscapes, cemeteries, government buildings, stadiums, and golf courses.

3. Types of Safety Bollards and Its Usages

Safety bollards are a simple yet effective solution for traffic management and health and safety compliance. There are many to choose from, and in this article, we’ll look at five different types of safety bollards and their functions.

Commercial locations where both off-road and on-road vehicles operate have their own risk points and challenges. Whether it’s an area where pedestrians and vehicles co-occur, or where a collision could cause severe structural damage.

Poorly managed website traffic can clearly put people at risk and incur serious health and safety penalties when the worst happens. You may also find that even a minor collision can interrupt your workday and lead to expensive repairs to your vehicle and/or building.

Strategically placed safety bollards can significantly offset these risks. The main purpose is to remind drivers and pedestrians of risks. Modern versions can also be used for many more purposes, as shown below in the five types of safety bollards.

1)Electric vehicle charging point protection

As the use of electric vehicles increases, workplaces are providing easily accessible charging ports in public and commercial parking lots. But this could open up a new vulnerability for you, as a vehicle collision or even wear and tear on your charging point could mean a costly repair or replacement.

Safety bollard manufacturers offer an effective solution to this modern problem; with safety bollards specifically designed to protect your electric vehicle charging equipment. They can be installed quickly and easily to protect electric vehicle charging points.

These products also help mark your electric car, van, and truck charging facilities and guide drivers to the best parking spots to use them. As standard, our product packages will cover light, medium, or heavy impact risks. In addition to our standard options, we can also provide bespoke solutions to provide optimal protection for your site’s electric vehicle charging points.

2)Flexible bollards and delineators

Our range of bollards and accessories for marking traffic routes is a great example of the role safety bollards play in alerting site users of risks. It’s hard to miss the carefully arranged series of flexible bollards and delineators in bright colors.

However, one of the advantages of this product range is that if something hits these safety bollards at low speed, they will bend and move before returning to their original shape and configuration.

This means that even if the vehicle does come into contact, no damage will be caused. Because of their relatively low cost, you can use flexible bollards extensively for both temporary and permanent traffic management.

3)Flexible outlines – parking space signage

This new addition to our range of versatile and long-lasting flexible bollards will help businesses manage traffic flow with flexibility and confidence. As employees return to the workplace and more in-person meetings take place, flexible contours indicating parking spaces will become an increasingly popular security solution.

However, collisions in parking areas are not the only problem this type of safety bollard can solve. You can also solve many confusions for your website visitors and ensure that driver parking logic is neat. Flexible contours with parking space indicators currently include options to mark disabled parking spaces or electric vehicle parking spaces.

This product is easy to spot, but unlike permanent parking signs, you can move it when needed. If vehicles do come into contact, the materials and design prevent structural damage to the vehicle and the bollard itself.

4)Bollard cover kit

This is undoubtedly one of the most cost-effective safety bollard options that still does its job in keeping vehicles flowing safely and the site accident-free.

These snap-on polymer molded bollard cover kits turn your existing posts into easy-to-find, secure structures. These kits come in a variety of high-visibility colors so you can categorize your posts. They’re also available in a variety of sizes, all with reflective tape for increased visibility in low light.

Since they require little maintenance, they are ideal 24/7 systems.

5)Removable core bollards

Like all of the safety bollards outlined here, the removable core bollard option is quick and easy to install and is highly cost-effective.

As the name suggests, removable drop-core bollards can also be quickly repositioned as your site’s traffic needs change. But they are not fragile. Made from steel and polyethylene, these safety bollards are designed to highlight and protect high-risk areas. This includes warehouse loading areas and external site entrances/exits.

All five colors feature 50mm reflective strips for increased visibility in low light.

4. What are Safety Bollards Made of?

Safety bollards are made from a variety of materials, including steel, concrete, plastic, cast iron, polyurethane, and wood.

1) Steel bollards

Steel bollards are the most common type of bollard and are commonly used in commercial and industrial applications. These steel bollards can be cast ductile iron, or stainless steel (particularly near the ocean where there is salt corrosion) and are available in a variety of sizes and shapes. Standard steel is often used in decorative premium bollard styles for stand-alone systems or as safety pipe covers. Steel bollards can be treated to minimize corrosion and rust. A steel bollard, for example, can be hot-dip galvanized or powder-coated to minimize corrosion.

2) Cast iron bollards

Cast iron is another material for making traditional-style bollards. It is a durable and popular traditional material for decoration and design enhancement, making it an excellent choice for a variety of uses.

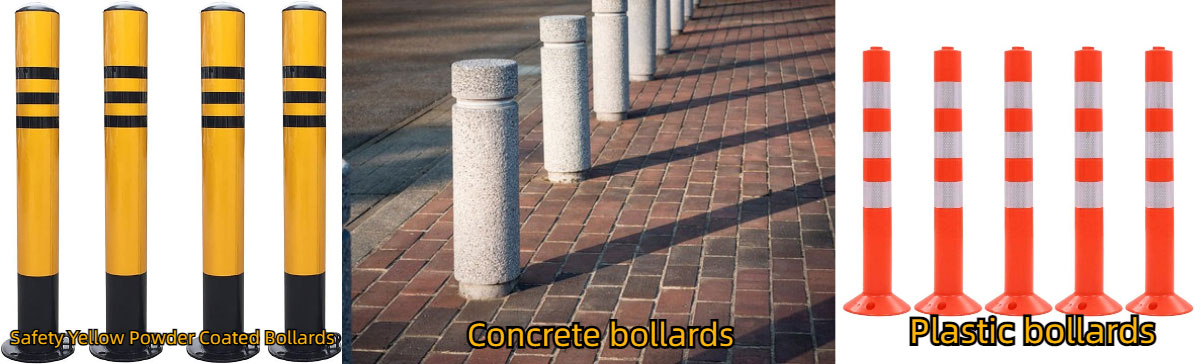

3) Safety Yellow Powder Coated Bollards

Safety bollards can also be coated with safety yellow powder to help people identify them in low-light conditions. These help reduce accidents or product damage. Australian Standard AS-2890 also proposes safety standards for bollards, including paint color, as well as reflectivity and visibility at night. More on that later.

4) Concrete bollards

Concrete bollards are extremely strong and durable, making them ideal for use in high-traffic areas. Concrete can be combined with steel pipe bollards or embedded steel reinforcement to create impact-resistant security features. It can form on its own to create attractive designs tailored to specific architectural designs. Or more commonly, steel bollards are filled with concrete once installed on site. This gives them extra ballast and resistance to impacts, such as those from larger trucks.

5) Plastic bollards

Temporary freestanding polyethylene bollards are often used in retrofit and parking applications because they are low-cost and low-maintenance. These types of bollards cover the applications and uses where the advantages of plastic come into play.

In contrast to polyurethane, plastic is rigid and will shatter on impact, but due to its malleability, it can be used to cover safety or impact-resistant pipes. It is economical to install plastic bollards in low-traffic areas.

6) Polyurethane bollards

Despite adverse weather conditions, polyurethane produces durable, UV-resistant, and flexible bollards. In many cases, polygonal bollards are chosen over traditional ones due to their functionality and cost.

7) Wooden Bollards

Wooden bollards are often used in residential applications, such as driveways or walkways, and where you are looking for more of an aesthetic finish that blends into the architectural design. However, in wooded or park areas, pressure-treated wood is sometimes chosen to complement the natural setting.

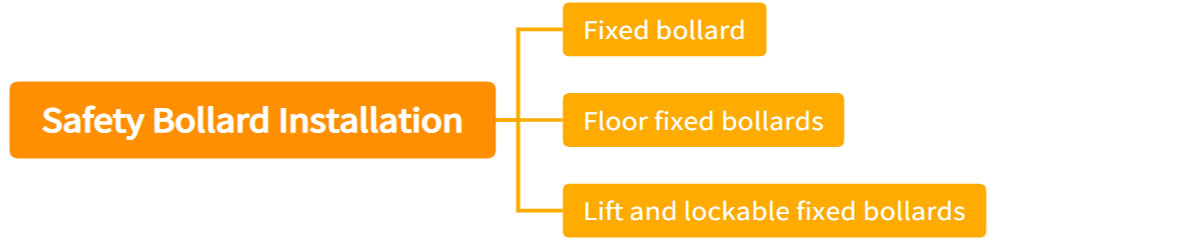

5. Safety Bollard Installation

Typically, bollards work best when the roots are anchored to a concrete foundation. However, there are exceptions, and we look below at all the different ways to install bollards.

- Fixed bollard

A specially designed section of the bollard is placed in the ground and secured with concrete. This is the safest way to install bollards. Anti-Ram bollards are placed deeper in the ground for added strength and support.

- Floor fixed bollards

Use when the subsurface may be vulnerable or weak, or when drilling down is not possible. A plate was added to the bottom of the bollard design and secured to the concrete surface using a suitable bolting system according to the manufacturer’s instructions.

- Lift and lockable fixed bollards

It is ideal for applications where bollards need to be replaced or removed from time to time.

6. Safety Bollards FAQs

The following are answers to safety bollards’ common questions.

1) What is the difference between concrete, steel, and polymer bollards?

Previously, concrete and steel bollards were common in traffic management. Polymer bollards have grown in popularity in recent years because they are durable and low maintenance. Industrial facilities use them to protect their assets and infrastructure from workplace vehicles.

While concrete and steel are strong and can protect against vehicle crashes, they are generally single-use safety products. Even a slight hit from a forklift can deform them. They usually need to be replaced after each impact. Polymers are flexible plastics that can bend and return to their natural shape under impact, making them ideal for busy workplaces where repeated impacts may occur.

Aotons’ security products are made from three-layer MemaplexTM polymer. They are designed for the busiest industrial facilities and tested to BSI PAS 13 standards.

2) In the different workplaces, what types of bollards are there?

Bollards have a variety of uses in the workplace, including:

- Guide traffic

- Define boundaries

- Protect people and property from vehicle strikes

There are two main types of bollards in industrial settings and they are:

- Standard Bollards

- Heavy Bollards

As the names suggest, the main difference between standard and heavy-duty models is the amount of force they can handle. Heavy-duty bollards are often used in areas where larger vehicles operate or where standard speed limits are high.

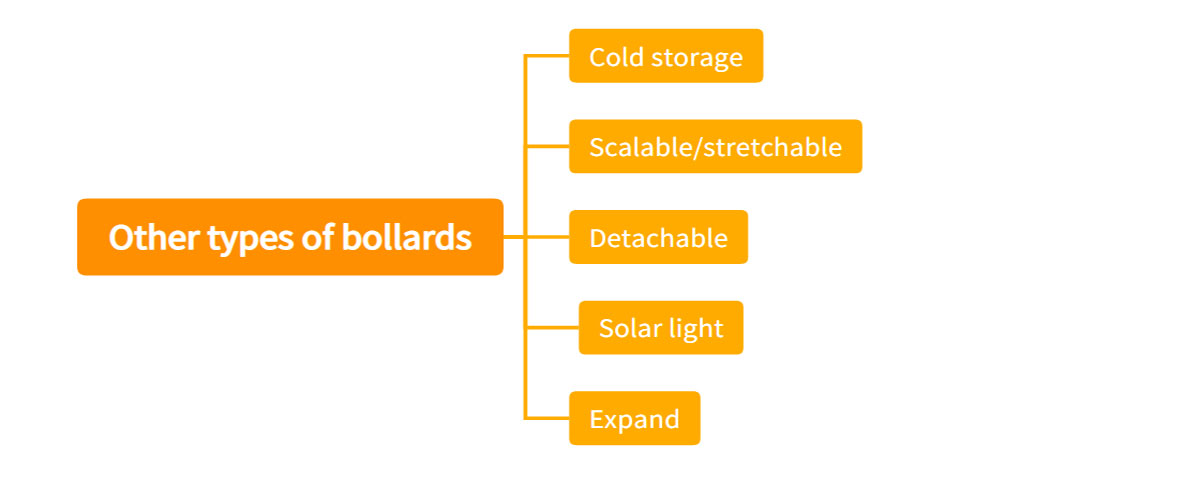

3) Are there other types of bollards?

The other types of bollards available reflect the type of scene in which they are placed. Some of the most common types are:

- Cold storage

- Scalable/stretchable

- Detachable

- Solar light

- Expand

Cold storage facilities require the same level of protection as the rest of a factory or warehouse, but with security systems that can function properly at lower temperatures. Specialty bollards are required in colder environments, because standard bollards can become brittle and brittle in the cold, increasing their failure rate.

Aotons Refrigerated Bollards are designed for cold storage facilities to protect structures and equipment from impact damage. They also provide a strong physical presence to keep drivers focused and restrain or guide vehicles and pedestrians.

- Scalable

The use of retractable bollards is usually restricted during certain hours and at entrances and exits. They are commonly used in streets, parking spaces, and areas around facilities. These bollards can be extended to prevent access and guide traffic when in use, and retracted to the ground when not in use.

- Detachable

Similar to retractable bollards, removable bollards are great for temporary use. However, they are lightweight and light enough to lock and unlock into underground receivers. If not in use, these bollards can be easily removed and stored elsewhere.

- Solar lights

Solar light posts are a great solution for outdoor lighting. They provide safety and visibility, are easy to install, and are environmentally friendly. With the assistance of the controller, the system can adjust the lighting accordingly according to the nighttime and regional activities

- Extension

Bollards of this type are much taller than conventional bollards. They are most commonly found in areas where higher levels of protection are required, eg in busy service yards where tall articulated trucks operate. If the truck needs to access the loading door, extended bollards are often used to ensure the door frame is properly protected.

In addition, extended bollards can provide visual guidance to drivers of higher than normal height, helping them avoid vulnerable assets or infrastructure.

7. Conclusion

At Aotons, we have a range of flexible polymer bollards and security systems to suit every need. Learn more about our heavy-duty and refrigerated bollards by speaking with a member of our team.

Leave A Comment