Aotons is a professional safety barrier manufacturer in China, we have our own independent research and development and have obtained a national patent. Patent Number: ZL 2017 2 0615451.5. Aotons designs and manufactures high-quality safety barriers to make environments safe wherever there is the movement of vehicles, goods, and people.

It is important to protect the workplace from accidents and incidents. We’ve created this handy guide to help guide you through the vast amount of information available.

1. Know the Basics

It takes a combination of common sense and planning to keep the workplace safe. By understanding and identifying potential risks, you can prevent or control them. Once the proper measures are in place, just use common sense to ensure everyone on site is adhering to them.

1) What is workplace safety?

Workplace safety refers to the rules, regulations, and guidelines that ensure a safe corporate and industrial working environment in day-to-day operations. Some of these rules will be outlined in official regulations, some specific to individual industries or workplaces, and some common sense ways of keeping people safe at work.

2) What are the risks of not keeping the workplace safe?

It is very important to keep the workplace safe to avoid any accidents or accidents. These events range from minor inconveniences preventing people from completing their duties to shutdowns. These serious issues can range from accidents that result in serious injury or even death to workers, to accidents that cause significant damage to valuable assets or infrastructure.

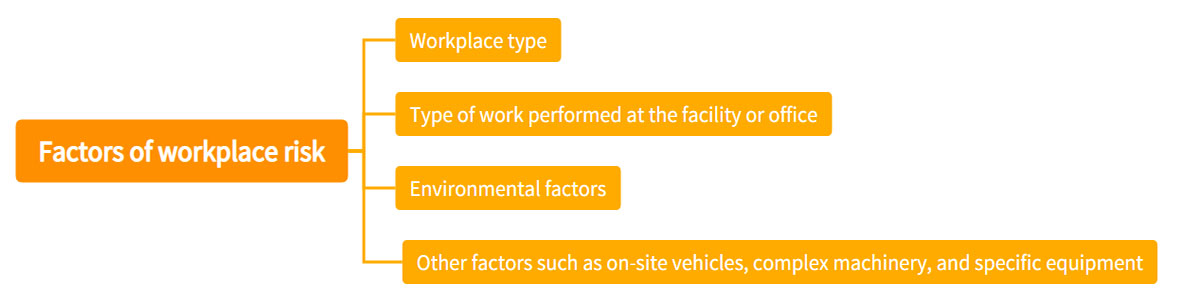

Risk varies based on several factors:

- workplace type

- The type of work performed at the facility or office

- Environmental factors – such as working outdoors, working at a specific temperature, etc.

- Other factors such as on-site vehicles, complex machinery, and specific equipment

In addition to the potential for injury or damage to people and assets, other consequences of not providing proper workplace protection include slowing or stopping production, downtime for repairs and maintenance, and the threat of prosecution or fines for not following proper safety measures.

Find out how we can help you assess facility risks and find the most effective solutions for your safety needs now that you understand the basics of workplace safety. Support can be provided on-site or remotely by a member of the AOTONS team.

2. Who and What is at Risk Regarding Workplace Hazards?

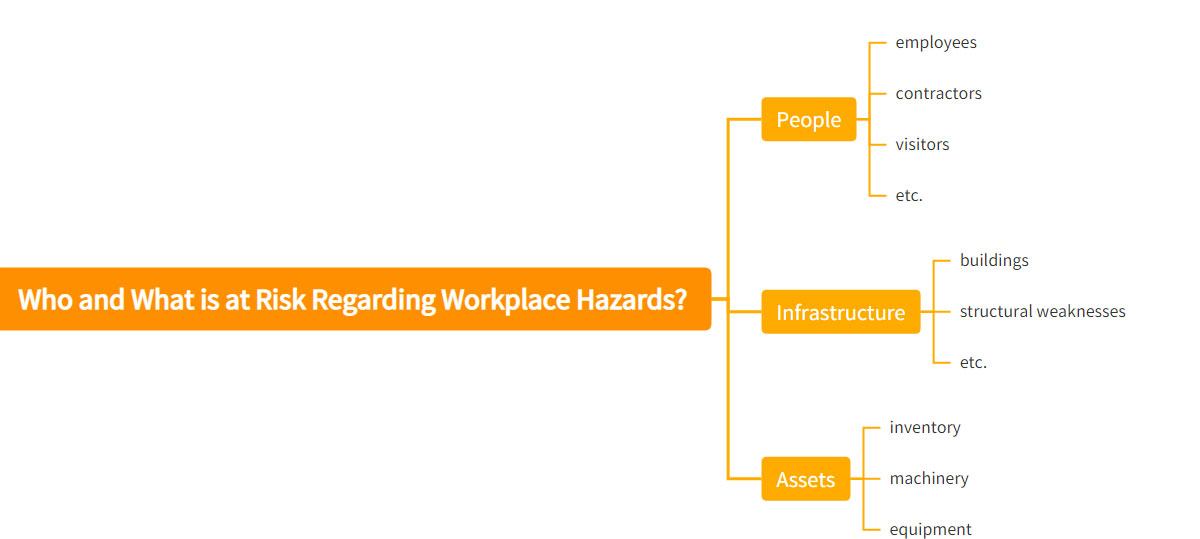

Three areas of concern are:

- People (employees, contractors, visitors, etc.)

- Infrastructure (buildings, structural weaknesses, etc.)

- Assets (inventory, machinery, equipment)

1) People

People need protection. Whether they are your employees, site visitors, contractors, or any other number of people who may be present in your facility at any given moment, steps need to be taken to ensure they can work and move through your facility safely.

2) Infrastructure

Damage to infrastructure, including walls, door frames, and floors, is very common in busy sites and facilities. However, it is important to have procedures in place to ensure these are properly protected as well. This could mean minimizing wear and impact in corners or providing greater protection to supporting beams or columns. It even maintains areas of your site that are prone to wear and tear, such as carpet or tile.

3) Assets

Assets are the most valuable things in your organization that deserve protection. You must protect machinery, vehicles, and equipment from injury and from power outages to ensure the smooth operation of your business.

Stocks are also classified as “assets”. Your inventory is valuable, so it’s important to ensure that the inventory itself, as well as the storage facilities you use, are properly protected.

The correct protection for each area can be determined once the people and risks are identified in your facility. Choosing the right workplace safety solution is what we do at AOTONS.

3. What are the Types of Workplace Risks?

There are a range of risks to be aware of in the workplace. As mentioned above, these depend on the industry and type of workplace. We have identified four main types of hazards that occur in most workplaces:

1) Physical Hazard

The workplace is prone to several hazards, some of which are common. The hazards include falls, spills, trips, exposed wires, and environmental factors such as excessive noise, high or low temperatures, and radiation sources.

2) Chemical Hazard

This refers to hazardous or highly volatile chemicals in the workplace. These may pose specific hazards to persons and assets. In many cases, these chemicals can cause irritation, burns, or death.

3) Biohazard

Biological hazards mainly refer to specific working conditions, including workers’ exposure to harmful bacteria, viruses, molds, and microorganisms, which are prone to infection. This includes raw sewage, hypodermic needles, and rotting food.

4) Ergonomic Hazards

When we talk about ergonomic hazards, we are referring to the way people work and the tasks or movements that can adversely affect them. This may include lifting heavy objects, repetitive movements, and work conditions that affect a person’s posture and comfort.

4. How to Spot Potential Hazards When Working in A Workplace?

The best way to identify potential workplace hazards is to conduct a thorough risk assessment. Inspecting your facility and observing how people work and interact with equipment and each other allows you to identify where accidents may occur, where people or assets are at risk of harm, or where appropriate safety measures are not being taken.

We can assist you in identifying risks associated with your website. At AOTONS, our team can conduct site surveys remotely or in person and help you find the right protection.

5. Who’s in Charge of Ensuring Workplace Safety?

Identifying risks and hazards on site is one thing, but how do you ensure those issues are being asked, and whose job it is to address them?

1) How do you keep your workplace safe?

Workplace safety can be achieved in many ways. These include:

- Accident report

- First aid materials and training

- Effective training of machinery and equipment operators

- Fire and Emergency Procedures

- Use Personal Protective Equipment (PPE)

Some of these are mandatory, others depend on the type of work environment and the responsibilities required of the personnel on-site. Regardless, it’s always important to know the safety measures that apply—even if they don’t directly relate to your job (e.g., fire and emergency procedures).

2) Who is responsible for keeping the workplace safe?

Employers have a responsibility to ensure that everyone and everything in their business is properly protected. It is their responsibility to identify potential risks and problems and take steps to prevent or minimize these incidents. This is a legal requirement for employers, but it is also in their best interest. Minimizing risk will reduce the chance of damage to valuable inventory or infrastructure, and avoid lengthy downtime due to on-site incidents.

3) Who is implementing security measures on-site?

Employers can delegate responsibility for leading workplace safety to designated members of the senior management team. This person may have one of several different titles; however, the most common is “Health and Safety Manager.” This person’s sole responsibility is to ensure that the workplace follows government guidelines and best practice regulations. They ensure that the facility and the people in it comply with government regulations.

Other roles that may have workplace safety responsibilities include:

- operations Manager and Director

- warehouse or factory manager

- office manager

- maintenance team

- human resources member

In the end, everyone is responsible for following workplace safety procedures and guidelines. By following the rules in the workplace, everyone can minimize the chances of accidents happening.

At AOTONS, we understand the health and safety challenges managers face, including finding affordable solutions and getting top management’s approval. For you to demonstrate how important on-site security is to your facility, we can provide you with the relevant information and dates. Feel free to contact us if you need assistance.

6. Safety Standards and Regulations

As important as safety is, there are clear rules and regulations on what to expect from employers and employees. This section looks at who controls and enforces the relevant security standards.

1) Who oversees workplace safety regulations?

The Occupational Safety and Health Administration (OSHA) is the US agency responsible for regulating and enforcing workplace safety. The Occupational Health and Safety Act was signed in 1970, creating OSHA. The agency’s mission is to protect the health, safety, and welfare of workers, and as such, its website is filled with information and guidance that is useful to both employees and employers.

In pursuit of its mission, OSHA develops workplace safety regulations, including setting health and safety standards, responding to complaints, and providing safety training, outreach, and education.

2) What are OSHA’s reporting guidelines for deaths, hospitalizations, and amputations?

OSHA establishes reporting standards that workplaces must follow, and part of Standard 1904 requires employers and those responsible for workplace safety and operations to report serious workplace accidents. For example, an employer and/or safety manager must report an employee’s death from a work-related accident within 8 hours. Likewise, events involving amputations, blindness, or requiring hospitalization must be reported within 24 hours.

3) What are the safety barrier rules in the workplace?

OSHA developed standards for guardrails and barriers in Standard 1910.29, which covers fall arrest systems and practices. More details about this standard are discussed in several Standard Interpretation Letters that clarify issues with this standard (and many others) in light of the public.

4) What are the employer’s responsibilities for hazardous substances in the workplace?

According to OSHA, employers have many responsibilities related to workplace safety, some of which focus on hazardous substances. Employers who use hazardous chemicals in the workplace must develop and implement a written Hazard Communication Standard (HCS) program and train employees on the hazards they face and the appropriate precautions to minimize risk.

Employers must also keep a copy of the safety data sheet for a known hazardous substance on hand. In addition to general standards for forklifts (also known as powered industrial trucks), OSHA has specific standards for forklift transport of hazardous materials.

5) Where can I find general regulations on workplace safety?

OSHA’s Standard 1910, which outlines rules and guidelines for workplace safety in the United States, provides dozens of standards to protect workers. OSHA also provides electronic tools to discuss best safety practices in the workplace. These include forklift operating tips and how forklift operators and pedestrians should be mindful of each other.

Other countries have agencies such as OSHA to protect the health, safety, and welfare of workers. Globally, there are International Standards Organizations that provide global standards for safety systems.

At AOTONS, our security solutions comply with relevant security standards and codes of practice. Our barriers are the most rigorously tested in the world, this is to ensure they provide ultimate protection. When you need it most, it gives you peace of mind. For more information, please contact us.

7. Summary

There is a lot to know about workplace safety, but much of it is common sense. With a little research, you can learn what risks exist in the field and how best to address them.

By creating advanced solutions, we strive to understand workplace safety and contribute to making industrial facilities safer. Polymer safety products, etc., are available from AOTONS. Get in touch with our team to learn how we can help. If you would like to learn more about how we can help you, please give us a call at +0532-86958235, send an email to info@aotons.com, or fill out the contact form below.

Leave A Comment