Maneuvering in confined spaces, with limited visibility or a moment of inattention: bang, it happened. Unplanned expenses for machinery and equipment are often caused by impact damage. However, costly repairs, production downtime, and even new purchases can easily be avoided.

With the right impact and crash protection, you can effectively protect your stock from impact. At the same time, you will minimize the risk of accidents at work. We’ll show you how to choose the right impact protection or barrier system for your needs.

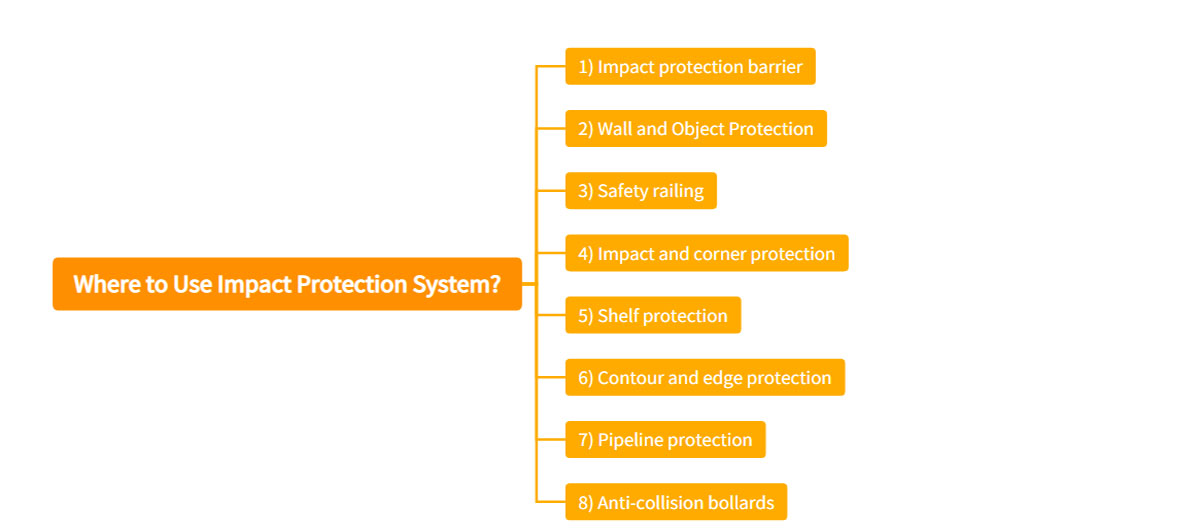

1. Which Impact Protection System is Best for My Application?

Here are three questions you should ask yourself before purchasing an impact protection system: What should it be protecting? Where should it be protected?

There are a few basic rules in play here: the more stable your impact protection system has to be, the heavier and faster the equipment it has to withstand in the event of a catastrophe. After all, a cart generates far less starting force than a forklift or truck. Therefore, as part of a risk assessment, it is important to identify potential hazards and select suitable impact protection as protective measures. The stability of impact protection depends not only on size but also on materials and installation techniques.

Depending on whether the impact protection is used indoors or outdoors, different requirements must be placed on the material. When used outdoors, non-galvanized steel products may rust as a result of collisions with equipment. As a result, your impact protection system for outdoor use should be made of corrosion-resistant materials.

1) Impact protection barrier

The impact protection barrier ensures effective impact protection during everyday operations. They help secure machines and equipment, secure sensitive work areas, or define traffic routes. Designs and shapes are available in a variety of sizes.

2) Wall and Object Protection

The wall protection profile is made of strong polyethylene (PE). They reliably protect walls from impacts, especially in areas of increased traffic – thus preventing damage to masonry or paintwork. Multiple profiles in one row allow flexible protection of walls of any length and height.

3) Safety railing

Railings are ideal for separating individual work areas from traffic routes, thus protecting plants and equipment from collisions. Railing systems can be customized to suit different operational requirements and are available in steel and plastic.

For example, I have a client. He is a custom paper tube packaging manufacturer. So his factory is full of machinery for producing paper tube packaging. In order to avoid the equipment from collision, he customized the warehouse guardrail from me and installed it in important areas. This not only protects important equipment in the plant but also effectively separates the work area from traffic routes.

4) Impact and corner protection

Freestanding columns, pillars, and pillars pose a constant threat to internal traffic. With the impact protection system for fastening to the pole, you can not only protect the obstacle itself but also the vehicle and equipment you work on. If particularly high column protection is required, we recommend the use of multiple protection profiles that can be mounted in the stack.

5) Shelf protection

The likelihood of collision damage increases when there are many vehicles and aids on the move. Racks can tip over when struck by heavy equipment, so they should be secured in corner areas and provided with impact protection. Products suitable for shelf-side protection are also available.

6) Contour and edge protection

These are self-adhesive or magnetically adhered elements made of highly flexible polyurethane foam. These can be flexibly cut to length and are suitable for attaching to flat smooth surfaces or edges. They are there to signal hazards and prevent impact injuries.

7) Pipeline protection

Often, for structural reasons alone, it is unavoidable to run pipes or lines in the open air near traffic routes or work areas. Damaged plumbing can be expensive! Therefore, you should use pipe protection profiles or special steel brackets to protect pipes and lines from collision damage.

8) Anti-collision bollards

At key points such as driveways or building corners, stamped protection bollards are an effective aid in delineating and protecting traffic routes.

3. Which Material Should I Choose for Impact Protection?

The Aotons impact protection range includes models made of steel and high-quality plastic. The purpose of impact protection should be considered when choosing a material. Depending on the application, different materials will have different properties. Generally speaking, the larger the diameter and the thicker the material, the greater the resistance of the crash plate.

If your company uses heavy and fast machines, you should use particularly stable crash protection. When using outdoors, weather conditions must also be considered. If you need a particularly strong impact protection system, you should choose a product made of hot-dip galvanized steel, which resists rust damage. Unlike metal crash protection, plastic crash protection is corrosion-proof – even after a collision with a vehicle, it will not rust.

However, galvanized steel is usually a better choice for outdoor use, as plastic products have the disadvantage of being less UV resistant. However, plastic has a significant advantage when it comes to crash protection, as the rounded and elastic material reduces impact forces and therefore also protects approaching equipment.

4. How to Install My Impact Protection System?

Once you have determined which impact protection system you need based on your risk assessment, the next step is to install the system. When installing it on the floor, you can choose whether to fix it with concrete or with screws. Setting in concrete is more time-consuming – but this is what keeps impact protection systems safest.

If you decide to tighten, you should always be sure to use the proper screws and pins. Take special care to place the product at a sufficient distance from the object to be protected. Impact protection that is attached directly to the object to be protected (e.g. edge or wall protection profiles), which can be screwed, self-adhesive, magnetic, or fixed by plug-in systems depending on the product. under any circumstances.

Leave A Comment