Bollard barriers are often located within restricted areas and parking facilities to prevent the entry of motor vehicles or to divert traffic by allowing pedestrians. In the current scenario, we are seeing an increase in the demand for automatic bollard guardrails for protection purposes. These smart automatic blocking bollards are used to allow authorized vehicles to enter restricted areas. These security bollards act as visual and physical barriers. In this article, we’ll tell you the difference between hydraulic and pneumatic bollards and how to choose one. Read on to learn more.

1. Hydraulic Bollard VS. Pneumatic Bollard: Definition

The following is a comparison of the definitions of hydraulic bollards and pneumatic bollards.

1) What is a hydraulic bollard?

Hydraulic bollards are automatic lifting bollards that use hydraulic motors as power units. They can be divided into hydraulic integrated bollards. , hydraulic split bollard. Their power units are hydraulic motors.

2) What is a pneumatic bollard?

Pneumatic bollards are raised and lowered by the air pressure inside the bollards. The pneumatic semi-automatic lifting roadblock is composed of a nested outer cylinder and an inner cylinder. A special key opens and locks the built-in gas spring to adjust the air pressure value to drive the telescopic rod, locking rod, lock head, and lifting limit. Bit blocks control lifting.

2. Hydraulic Bollard VS. Pneumatic Bollard: Application

The following are the uses of hydraulic bollards and pneumatic bollards.

1) Application of hydraulic bollards

Fixed metal bollards are the most common. They are generally painted steel columns about 36 meters high, with cement poured inside and installed on the ground. Some bollards are cube-shaped, but most are cylindrical structures with angled or flat brims. Bollards come in many sizes, colors, textures, shapes and functions. They are either fixed, movable or retractable, and can also be used as a decoration to decorate the original steel tube bollards.

2) Application of pneumatic bollards

- Gates of important units such as state agencies: install lifting roadblocks to effectively prevent vehicles from outside units from entering and illegal vehicles from breaking in.

- Pedestrian street: Elevating roadblocks are installed at pedestrian street intersections. The roadblocks are usually raised to restrict the entry and exit of vehicles. In case of emergency or special circumstances (such as fire, first aid, leadership inspection, etc.), the roadblocks can be quickly lowered to facilitate the passage of vehicles.

- Road isolation belt: Lifting roadblocks can be used in non-fully enclosed road isolation belts to prevent vehicles from turning left or making a U-turn. In case of special circumstances such as road construction and road obstruction, roadblocks can be put down to divert vehicles.

- Multi-purpose square: During the day, roadblocks are raised to prevent vehicles from entering the square. At night, the square is used as a temporary parking lot. When the roadblocks are lowered, vehicles can enter and park.

- Open park: Lifting roadblocks are installed at the intersections of open parks. The roadblocks are usually raised to block the passage of vehicles, but visitors can pass freely. In special circumstances, lower the lift barricade to facilitate vehicle passage.

- Residential areas, banks, schools, and other places that restrict vehicle entry and ensure the effective use of fire escapes.

In fact, there is no big difference in application between hydraulic bollards and pneumatic bollards.

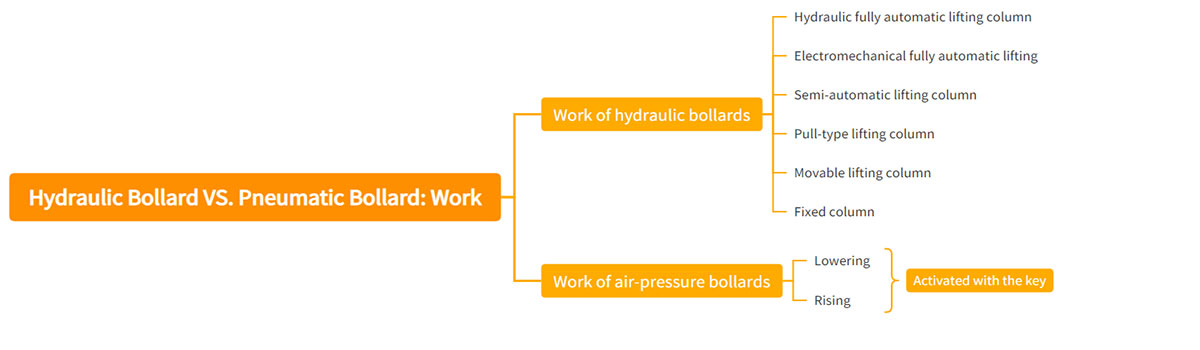

3. Hydraulic Bollard VS. Pneumatic Bollard: Work

The following is a comparison of the work differences between the two.

1) Work of hydraulic bollards

Hydraulic bollards can be divided into the following types, and the methods of work are different depending on the type.

#1. Hydraulic fully automatic lifting column

Hydraulic oil serves as the driving medium. There are two control methods, namely, driving the column up and down through an external hydraulic power unit (the driving part is separated from the column) or a built-in hydraulic unit power unit (the driving part is placed inside the column).

#2. Electromechanical fully automatic lifting

The lifting and lowering of the column is driven by the motor built into the column.

#3. Semi-automatic lifting column

The ascent process is driven by the power unit built into the column, and the descent is completed by manpower.

#4. Pull-type lifting column

The ascending process requires manual lifting, and the descending process relies on the column’s own weight.

#5. Movable lifting column

The column and the base are designed separately, and the column can be stowed away when it is no longer needed for control.

#6. Fixed column

The column is directly fixed to the road surface.

2) Work of air-pressure bollards

Usage:

- Lowering: Activated with the key, the release mechanism applies pressure to the top of the bollard to lower the bollard back into the ground and lock automatically.

- Rising: Activated with the key, applying pressure to the top of the bollard and releasing the pressure will raise the bollard to its highest position.

4. Hydraulic Bollard VS. Pneumatic Bollard: Maintenance

In order to maintain hydraulic bollards well, we must use hydraulic oil regularly. This increases maintenance costs. But in pneumatic bollards, the maintenance cost is less as we use air compressors.

The price of hydraulic bollards is higher compared to pneumatic bollards because hydraulic bollards can rise and fall smoothly compared to pneumatic bollards.

5. Functional characteristics of pneumatic bollards

The following are the advantages of pneumatic bollards.

1) Anti-collision

The 10mm thick stainless steel cylindrical bottom base is cast with additional cement. Compared with similar products, the impact resistance of this product is greatly improved, thereby ensuring that customs clearance vehicles cannot cross blocking roadblocks. The lifting column part of the pneumatic bollard adopts an overall design. The column body can be considered a more impact-resistant design, so it has strong impact resistance and has real anti-terrorism significance.

There are only low-cost pneumatic pistons in pneumatic bollards. Even if the cylinder and internal piston are damaged due to an accidental collision, maintenance costs are low and very simple. The lifting and lowering of the lifting column is driven by compressed air, which runs quickly and can be used frequently.

2) Waterproof

The internal device adopts a fully sealed design, which greatly improves the waterproof performance compared with similar products and avoids repairs due to water intrusion into the movement. The air compressor is installed in the control box, which can be placed at a suitable location on the ground. There is only a pneumatic piston in the cylinder, no strong electricity, and no motor. And the working voltage is safe 12V, 24V, safe and reliable to use! Pneumatic bollards can work normally, reliably, and safely even if they are completely submerged in water for a long time.

3) Pneumatic bollards are environmentally friendly and pollution-free

The pneumatic bollard lifting bollard system is clean and convenient to use and maintain and does not cause any pollution to the environment. Due to the use of compressed air and quick connectors, installers only need simple preparations to start work, and the requirements for maintenance personnel are not high.

There’s no need to clean and it’s easy to drain thanks to the hose! If a gas line is damaged, it is easy and cheap to replace. If there is an air leak in the pneumatic bollard lifting system, the compressor will automatically pressurize and the equipment can continue to work normally within a reasonable period of time. Moreover, there are no air leakage costs, no environmental pollution, and no maintenance costs.

4) Easy to install

Compared with the fully automatic hydraulic lifting roadblock, the installation of semi-automatic lifting roadblocks is characterized by the fact that it does not require an external power system, and the construction is convenient and fast.

5) Simple operation

Compared with the fully automatic hydraulic lifting roadblock, the manual key lifting locking roadblock is characterized by shorter lifting and landing times, safety, and reliability.

6. Installation of air pressure bollards

Installation method: Find the center point where the roadblock needs to be installed, dig a hole 60cm in diameter and 70cm deep, spread about 10cm of sand and gravel on the bottom, and then put in the roadblock. Make it flush with the ground, and then pour cement around the barricade until it is flush with the ground.

7. Hydraulic bollards or pneumatic bollards?

Here, I would like to explain to you the difference between hydraulic bollards and pneumatic bollards. As the name suggests, in hydraulic bollards, we use hydraulic oil to generate a large amount of pressure. The power is required to raise and lower hydraulic bollards, and with pneumatic bollards, compressed gas is used for power transmission.

Generally speaking, as the medium of automatic bollards changes again, one question arises: Which are the best automatic bollards? Both hydraulic and pneumatic bollards are ideal for heavy-duty operations. However, the use of these bollards depends on the installation location.

If you are installing these self-raising bollards in a low-temperature area, use pneumatic safety bollards because if the temperature is very low, the hydraulic fluid will become thicker and may disrupt the operation of the bollard. So we recommend using pneumatic bollards in low-temperature areas.

8. Conclusion

That’s the comparison between hydraulic bollards and pneumatic bollards summarized in this guide for you. I believe that after reading this article, you already know how to choose. If you have any further questions, please contact Aotons for consultation.

Leave A Comment