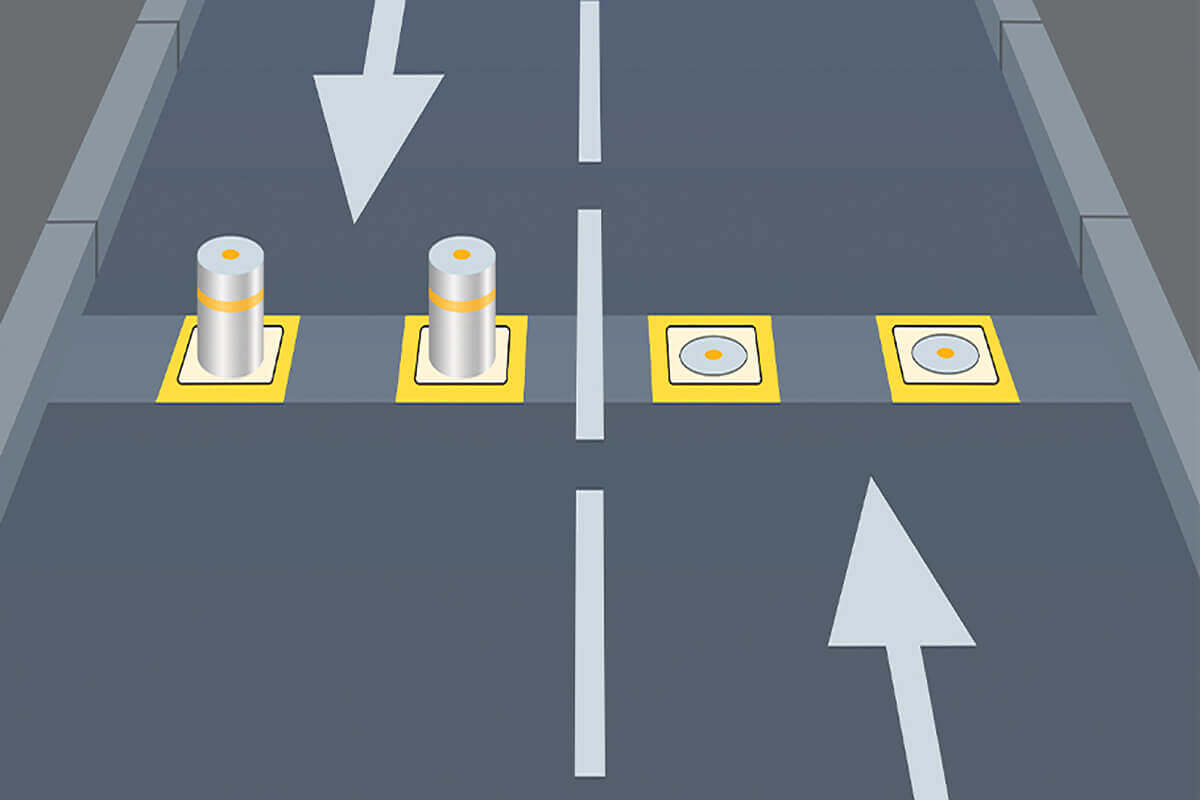

I believe you often see a row of metal guardrails on the street, especially next to the sidewalk. Some guardrails can also be raised and lowered automatically via remote control. This is a hydraulic bollard. In today’s guide, we’ll take a closer look at what a hydraulic bollard is and how it works. Read on to learn more.

1. What is an automatic hydraulic bollard?

Automatic hydraulic bollards are made of steel and are raised above the ground to restrict access and prevent intrusion into premises where access must be restricted for safety reasons. One of the main reasons to install automatic bollards is to protect parking spaces that are often targeted by vandals and criminals. Additionally, more and more homeowners are installing automatic bollards on their driveways. This is because bollards can act as a powerful barrier against strangers.

1) Hydraulic bollard size

Hydraulic bollards come in different sizes:

- Available diameters are 168 mm, 219mm, 273mm, and 325mm.

- Height (above ground) options include 400 mm, 600mm, 800mm, 1000mm, 1200mm and 1500mm.

- As for thickness, you can choose 6 mm, 8mm, 10mm, 15mm, and 20mm.

2) What is the standard telescopic column distance?

According to industry standards, the general installation distance of telescopic bollards is usually between 0.8 and 1.5 meters. The purpose of the device is to effectively prevent unauthorized vehicle access while allowing barrier-free access for pedestrians and e-bikes.

2. Working principle of automatic hydraulic bollards

The electro-hydraulic lifting column is an automatic lifting bollard with a motor and a hydraulic cylinder as the power unit. Including hydraulic integrated lifting column and hydraulic split lifting column. Their power units are hydraulic motors. Lifting columnIntegrate the motor and hydraulic cylinder to form a hydraulic drive system. The motor drives the hydraulic cylinder piston rod to lift and control the column. Vehicle lifting effectively ensures traffic order and the safety of major facilities and places by restricting passing vehicles.

The mechanism of automatic hydraulic bollards includes the use of a hydraulic power unit (HPU), a control system including a programmable logic controller (PLC), and a bollard shaft.

- Use a remote control (or an access control system that includes devices such as card readers, keypads, or biometric sensors) to send signals to the control system.

- The control system analyzes and processes through PLC, and controls the relay to start the contactor and start the motor according to the instructions.

- After the motor is started, it drives the gear to rotate and presses the hydraulic oil into the hydraulic cylinder through the integrated valve. By pushing the hydraulic cylinder to extend and retract, the bollards retract flush with the ground, allowing authorized vehicles to pass.

- Once passage is denied, the PLC sends a signal to the HPU, which then pumps hydraulic oil into the automatic bollards to raise them.

Main components of hydraulic bollards

- Bollard: 304 stainless steel seamless steel pipe, strong load-bearing, and impact resistance; high waterproof level. Retractable bollards are embedded in designated locations in driveways or gates and can be raised and lowered via remote control (or access control system).

- Hydraulic transmission station: consists of a fuel tank, manual oil pump, a complete set of hydraulic solenoid valve groups, high-power motors, oil pumps, oil cylinders, oil meters, high-pressure hydraulic oil pipes, etc. It is the power source of the entire roadblock system. The device is installed on the side of the telescopic roadblock and used in conjunction with it.

- Electrical control system: It consists of a PLC control panel, leakage switch, no contact noise, and a high-life contactor with a precise start-up time setting.

3. Types of automatic rising hydraulic bollards

There are various types of hydraulic bollards depending on the traffic volume and population in the area. These include:

- Pedestrian bollards: Decorative pedestrian bollards are used in various public spaces such as sidewalks, parks, etc. They are used to mark the boundaries of buildings. Pedestrian bollards can also be equipped with reflectors and lighting devices to regulate the road at night.

- Safety bollards: They are used to manage pedestrian and vehicular traffic flow. These bollards also provide security to buildings by stopping vehicle impacts. Most security bollards are made of steel and installed on a foundation of concrete base slabs. Safety bollards are further divided into semi-automatic, fixed, and automatic bollards based on their mode of operation.

- Crash bollards: Crash bollards are safety bollards often placed at government and military installations to provide a heavy deterrent in the event of a possible vehicle collision. Some manufacturers also offer anti-collision bollards that can deter troops as a counter-terrorism function. A crash rating is the result of testing that ensures a bollard will be able to stop a vehicle of a certain size at a certain distance. The most common ratings are the K rating and the M rating.

- Fixed bollards: Fixed bollards are the most popular type of bollards. They are permanent, persistent, and deterrent. Typically, they are made of steel and filled with concrete. Although they offer better security, they are not suitable for garages and parking lots that require free entry in some cases.

- Removable/Retractable Bollards: Temporarily install removable bollards to block off designated areas. They can be placed and removed at any time. Locking pins and sockets secure the bollards, however, they can also be removed to facilitate vehicle cleaning.

- Semi-automatic bollards: Semi-automatic bollards are commonly used in parking spaces where parking spaces need to be blocked off during certain times of the day. They are also used in areas with low traffic volume. Semi-automatic bollards are raised by unlocking a mechanical key, causing the bollard to raise automatically. Once the bollard is fully lowered, it automatically locks in the same position.

- Automatic bollards: Automatic bollards can automatically retract and rise out of the ground according to the controller. Most of these bollards use motors or hydraulics to lift. They are a reliable and flexible method of flow control without any manual intervention.

4. What are the advantages of hydraulic bollards?

The following are the advantages of hydraulic bollards.

1) Unparalleled security

Hydraulic automatic bollards provide an unparalleled level of security, ensuring that unauthorized vehicles cannot enter secure areas. With their robust construction and powerful hydraulic operation, these bollards act as a strong deterrent to potential threats.

2) Flexibility of access control

Hydraulic automatic bollards can be easily adapted to various access control requirements, providing excellent flexibility. They can be integrated with advanced systems such as key card readers, walkie-talkies, or license plate recognition technology to provide seamless access to authorized personnel while effectively limiting access to unauthorized vehicles.

3) Durability and reliability

Hydraulic automatic bollards are made of high-quality materials such as stainless steel to withstand extreme weather conditions and heavy-duty use. Even with frequent use, its hydraulic operation ensures smooth and reliable performance, making it a reliable long-term investment.

4) Easy integration and control

Hydraulic automatic bollards can be easily integrated into existing access control systems, making them easy to install and operate. In addition, these bollards can be controlled remotely, making it possible to effectively manage access points without compromising security.

5. Application occasions of hydraulic bollards

The following are applications of hydraulic bollards.

1) Protection of critical infrastructure

Hydraulic automatic bollards play a vital role in protecting critical infrastructure sites such as government buildings, power plants, and airports. By effectively controlling access, these bollards mitigate potential security threats and secure sensitive areas.

2) Commercial and retail premises

Many commercial and retail establishments utilize hydraulic automatic bollards to control vehicle access to their premises. These bollards provide an effective solution for managing parking areas, restricting access during non-business hours, and ensuring the safety of customers and employees.

For example, I have a friend who is a wholesale wax beads business. Once he invited me to visit his shop. I found him installing hydraulic bollards at the entrance to the parking lot. He said this not only makes it easier to manage the parking area but also protects the safety of guests.

3) Residential Community

Residential communities, gated communities, and apartment buildings benefit from the installation of hydraulic automatic bollards. These bollards increase security by allowing only authorized vehicles to enter, thereby reducing the risk of unauthorized access or vandalism.

4) Public Spaces and pedestrian areas

In urban areas with pedestrian areas or public Spaces, hydraulic automatic bollards play an invaluable role in controlling vehicle movement. By strategically placing bollards, city planners can create safer environments for pedestrians, prevent unauthorized parking, and maintain the overall integrity of designated areas.

6. How much does a hydraulic bollard cost?

The cost of hydraulic bollards depends on a variety of factors such as materials, installation, and size. Generally, prices range from $200 to $500 per unit. It’s worth noting that the cost of these bollards will also vary based on the features included, such as lighting or locking mechanisms. When considering purchasing hydraulic bollards, it is important to also consider ongoing maintenance and repair costs to ensure they remain functional over time.

Overall, the cost of hydraulic bollards can be a significant investment, but they are an important step in ensuring the safety of your property.

7. Installation of hydraulic bollards

Here is a step-by-step guide to bollard installation:

- Digging hole, 800mm wide, 1300mm deep.

- Lay a permeable layer and use sand and small stones to make a permeable layer with a height of 200-300mm at the bottom of the foundation pit.

- Fix hydraulic bombardment.

- Fix the hydraulic column with angle iron so that it is 5 mm above the ground.

- Choose whether to lay drainage pipes according to the area.

- Wiring debugging after the hydraulic column is fixed.

- Finally, fill the gaps with concrete and wait for it to dry before use.

- Ensure regular maintenance of bollards and their foundations to prevent any damage or wear and ensure their long-term effectiveness.

8. Routine maintenance and upkeep of hydraulic bollards

In order to extend the service life of bollards, stabilize performance, and reduce maintenance, daily care and maintenance of bollards and guardrails must be done. Here is the task list

- Check the bollards for any signs of damage, such as cracks or dents.

- Check the hydraulic oil level and refill if necessary with the recommended hydraulic oil type.

- Check hydraulic hoses for signs of leakage or wear and replace as necessary.

- Lubricate all moving parts with the appropriate lubricant to ensure smooth operation.

- Use a soft cloth and mild detergent to clean bollard rails, avoiding the use of abrasive cleaners or solvents that may damage finishes or components.

- Use the control system to check the operation of the bollard to ensure that it rises and falls smoothly without abnormal noise or vibration.

- Remove any debris or obstructions that may impede the bollards, such as leaves or small rocks.

- Make sure the bollard guardrails are free of any moisture or water, especially in cold climates where freezing can damage hydraulic systems.

- Document any maintenance performed, including fluid refills, hose changes, or any other repairs or adjustments to bollard guardrails.

By performing these routine care and maintenance tasks, you can help ensure that your bollard guardrail operates smoothly and is reliable for the long term.

9. FAQ

Here are answers to frequently asked questions about hydraulic bollards.

1) What is the maximum load-bearing capacity of hydraulic bollards?

The load-bearing capacity of hydraulic bollards can reach more than 80 tons, and they are suitable for use in high-security areas such as government buildings, military facilities, and airports.

2) How deep underground do hydraulic bollards need to be installed?

Generally speaking, hydraulic bollards need to be installed to a depth of 1300mm to 1400mm below the ground.

3) How long does it take for hydraulic bollards to fully retract and deploy?

Telescopic bollards are designed to fully retract or extend in 3-4 seconds.

4) Can hydraulic bollards be customized to meet specific requirements?

Yes, hydraulic bollards can be customized to meet specific requirements such as size, color, and operating characteristics.

5) What materials are used for hydraulic bollards?

The materials used to manufacture hydraulic retractable bollards typically include high-strength steel and other durable materials. Aotons uses 304 stainless steel to produce telescopic bollards due to its excellent ability to withstand impact and resist damage from environmental factors such as weather and moisture.

6) Can hydraulic bollards be integrated with other safety systems?

Yes, hydraulic bollards can be integrated with other security systems such as surveillance cameras and access control systems to enhance overall security measures.

7) Are hydraulic bollards a reliable safety solution?

Yes, hydraulic bollards are a reliable safety solution as they are designed and manufactured to strict standards and undergo rigorous testing before installation.

8) What is the service life of telescopic bollards?

The service life of telescopic bollards varies based on usage and environmental conditions. Typical life span range is 5 to 15 years.

9) Can hydraulic bollards be used in severe weather conditions?

Yes, hydraulic bollards can be used in severe weather conditions as they are designed to withstand extreme temperatures, rain, and snow.

10) Can hydraulic bollards be controlled remotely?

Yes, hydraulic bollards can be controlled remotely using a number of different methods, such as a physical key, a remote control, or a signal from an access control system.

10. Conclusion

The above is the introduction of hydraulic bollards in this guide. If you are interested in hydraulic bollards, please contact Aotons for a quote.

Leave A Comment