There are many types of impact protection barriers, but do you know how to choose the right one? In today’s guide, we’ll look at the types of crash barriers and how to choose the right one. Read on to learn more.

1. What is the impact protection barrier?

Impact protection barriers are a critical engineering control when using forklifts within a facility or warehouse. Impact protection barriers are physical barriers designed to protect building components, storage racks, objects, equipment, materials, and personnel from forklifts or other vehicles that may be used in danger. Impact protection barriers can include specially constructed guardrails, posts, and bollards that stop the forces and minimize the damage that a forklift may cause. Impact barriers are the preferred protective measure because they are tangible and designed for impact.

Painted lines or marking tape on the floor are not effective in preventing collisions because they do not stop the vehicle from being struck. Line drawing or marking tape is a useful visual management control that can prevent hazards as they are warning signs. However, they are not sufficient to ensure the safety of workers, objects, or materials as they only show the path of travel. They won’t stop a forklift from hitting a worker on the walkway, or stop a worker from walking into a designated forklift area. Another benefit of using physical impact barriers is that workers feel safer when walking around the forklift area.

For example, I have a friend who is a drain strainer manufacturer. Once he invited me to visit his factory, and I saw that he had installed a lot of impact protection barriers next to the shelves of the factory. He introduced me to the variety of drain strainer stock placed on the shelves. Installing impact protection barriers next to the shelves can prevent damage to the shelves, thereby protecting the drain strainers on the shelves from damage. In the past, he has tried drawing lines or marking the floor, but he says this method is not the best way to protect the safety of the product’s employees. So he adopted the method of installing impact protection barriers.

Therefore, physical impact barriers are highly recommended to protect workers and materials from potential collision hazards associated with forklift use.

2. Types of impact protection barrier

Impact protection barrier shall adequately protect equipment racks, personnel, building components, objects, or other materials from forklift collisions. They should be designed and constructed of sturdy materials that can absorb the impact of a forklift without cracking or collapsing. OSHA states that yellow should be the primary color used to designate “cautions” and mark physical hazards in the workplace. Yellow impact protection barriers are bright and highly visible to workers and forklift operators, making them the preferred color.

1) Bollards

Impact barriers such as bollards should be installed and positioned accurately in front of the material you want to protect. The bollards should be able to sufficiently surround the material you want to protect to ensure that a forklift cannot hit it. Bollards come in a variety of strengths, heights, and widths, so buy the one that best surrounds the material. The best practice for adequate protection is to maintain a minimum of 12 inches of clearance between the object being protected and the bollard. Installation instructions should be used before installing and anchoring bollards.

2) Guardrails and pillars

Impact protection barriers such as guardrails and posts should cover the area around the material, object, or walkway you want to protect. There are many types of railing configurations that can be purchased, such as corner railings or straight railings. If you plan to screen the intersection of two walls, the corner of a machine, or a corner where workers turn in an aisle, then a corner configuration will work best for your application. If you must protect the front of an electrical panel, the sides of a storage rack, or a straight walkway for workers, a straight design is best.

The posts that hold guardrails in place should be strong, durable, and flexible to absorb the impact of a forklift collision and protect the guardrail system during a potential forklift accident.

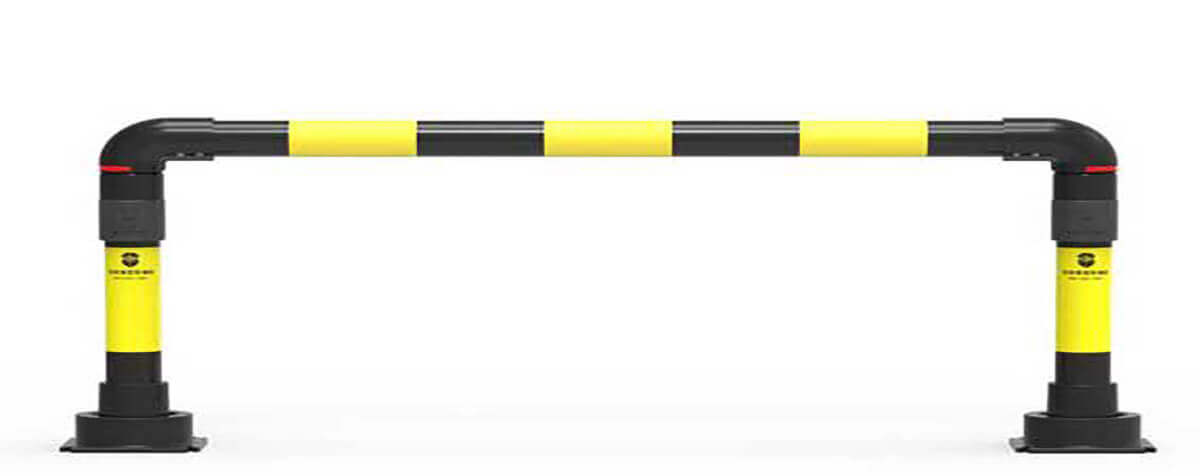

3) N-shape impact protection barrier

The N-shaped impact protection barrier is suitable for placement on both sides of the road where protection is required, and its base structure adopts a patented design. Energy-absorbing elastomers are added to the bottom of the bollard to achieve buffering and protection functions. When impacted, the N-shaped impact protection barrier can be tilted and buffered within 20° to absorb impact energy and minimize damage caused by column impact. After the tilt angle reaches the limit, it is in a rigid state, protecting important assets such as tankers from damage; after a collision, the column returns to an upright state and the column is intact, which greatly extends the service life of the N-type impact protection barrier.

The installation is simple and easy to operate, just use the anchor screws to firmly install the bumper, and the installation can be completed in 15 minutes. Assume that the crash bollard is affected beyond the design limits. At this time, you only need to replace the column or beam without removing the fixed anchor bolts, making maintenance simple and convenient.

4) M-shape impact barrier

In addition, there are M-shaped impact barriers. The difference between it and the N-shaped impact barrier is that there is an additional bollard for support. Its performance and functionality are consistent with the N-shaped impact barrier.

3. How to choose an impact protection barrier

When choosing the right impact protection barrier, you should consider the following factors.

1) Easy to customize

When using an impact protection barrier, you want to work with a company that can customize the product to your specific needs. Impact protection barrier should be able to be customized to the object, material, or walkway you want to protect. This can include straight, corner, or angled guardrails or guardrails of varying lengths.

2) Easy and quick replacement

If a forklift hits an impact protection barrier, does the entire guardrail need to be replaced? Certain guardrail systems allow individual sections of the railing (approximately a few feet) to be removed so they can be quickly replaced. If a forklift hits a guardrail system, you can replace a small section of the guardrail instead of the entire railing. It’s more cost-effective to replace a small part without breaking the budget. When replacing your guardrail, you also want it to be as simple as possible.

Some barrier systems can be removed by lifting the barrier from its slot for minimal and easy replacement. Because the mounting posts secure the barrier to its foundation, the railings can be easily removed if they need to be replaced.

3) Easy to expand or relocate

You want to work with a company that offers crash barrier options for expansion or relocation. If you need additional barrier length for more protection, you have the option to quickly extend it. Barrier can also move if equipment, objects, or materials are moved. They can be reconfigured or moved to a new location.

4) Cost

Of course, there are many manufacturers of impact barriers, but the most important thing to consider is your budget. In a comprehensive comparison, it is best to choose a guardrail with a higher safety factor but a lower cost.

4. What are some popular impact protection barrier manufacturers?

There are many manufacturers who can provide impact barriers for your workplace. Here are some popular impact protection barrier manufacturers.

1) Aotons

Aotons is a professional safety barrier manufacturer in China, they have independent research and development and obtained national patents. In the past 6 years, Aotons has developed 3 series of patented safety guardrails, including parking guardrails, industrial guardrails, and automatic bollards. Their flexible safety barrier solutions have served industries such as petroleum, logistics, automotive manufacturing, chemicals and pharmaceuticals, food and beverages, and more.

Up to now, Aotons’ safety guardrails have not only sold well in the domestic market, but also exported to more than 30 countries and regions including Chile, France, Sweden, Mexico, Malaysia, New Zealand, Brazil, Colombia, Peru, Australia, and South Africa. If you are looking for a safety barrier for your project, Aotons are a great choice.

2)Omega Industrial

Omega Industrial’sImpact Barriers are easy to install, replace, expand, and reposition. They are a leading provider of customizable personal safety products made from durable materials for superior strength and reliability.

3)Heartland Steel Products

Heartland Steel Products is another great manufacturer of reliable impact barrier products. You can choose a specific length of guardrail from three to ten inches or request a specific size. They are also available in single, dual, or triple rail applications.

5. Conclusion

The use of impact protection barriers in roadways or warehouses is a recommended safety best practice to protect people, objects, materials, equipment, and building components from potentially hazardous damage. Impact protection barriers are vital to a safe work environment, minimizing injuries and property damage. I believe that after reading this article you can quickly find the impact protection barrier manufacturer you want.

Leave A Comment