In this guide, we will cover many questions you may have about finding, purchasing, and installing the most effective safety barriers for your facility. Please read on to learn more.

1. What is a safety barrier?

Let’s understand the definition, components, and applications of safety barriers.

1)Definition

A safety barrier is a reinforced fencing structure used to protect valuables such as people, buildings, machinery, and inventory from unnecessary damage caused by vehicles and other moving objects. Safety barriers can also be used to create designated routes and isolate different types of traffic, such as sidewalks and vehicle routes.

2) Components of a safety barrier

While the barriers may vary between safety barrier manufacturers, the basic components are:

- End post

- Center column

- Railway

3) Where are safety barriers used?

Safety barriers are widely used in various industries, sectors, and workplaces. They are primarily used in busy industrial facilities where on-site vehicles are common, such as:

- Factory

- Storehouse

- Delivery center

- Airport

- Parking lot

2. What are the usages of safety barriers?

Generally, safety barriers are used to:

- Protect

- Isolation

- Define route

- Pedestrian support

1) Protect

The most common use of safety barriers is to provide protection. This can protect any number of things, such as people, machines, vulnerable structural spaces in buildings or facilities, inventory, and goods. Safety barriers prevent the entry of vehicles and smaller manually operated material handling equipment such as pallet trucks.

2) Isolation

Another important use of safety barriers is isolation. Separation refers to the separation of one object or person from another. Safety barriers can be used to isolate:

- A person in a moving vehicle

- Labor and machinery from hazardous or hazardous areas

- A workspace or another workstation

- Opposite lane

3) Define the route

As with isolation, safety barriers can be used to identify and mark specific routes and paths. This can include vehicular routes throughout the facility, safe walkways for employees and visitors, and more specific routes such as one-way systems in busy venues.

For example, I have a friend. He was a stand up pouch manufacturer, and his factory housed many of the machines that produced the stand up pouch. To prevent workers from touching machines while walking, he created a walkway in the factory with safety barriers. This not only protects the safety of workers but also protects the safety of the assets of the plant.

4) Pedestrian support

In addition to creating sidewalks, safety barriers provide the necessary support for foot traffic. Most pedestrian barriers include a handrail to provide additional support and make it easier for people to move through the facility.

With the world’s first advanced polymer safety barrier, Aotons is the market leader when it comes to traffic management, pedestrian isolation, and protection. Making workplaces safer is what we know best.

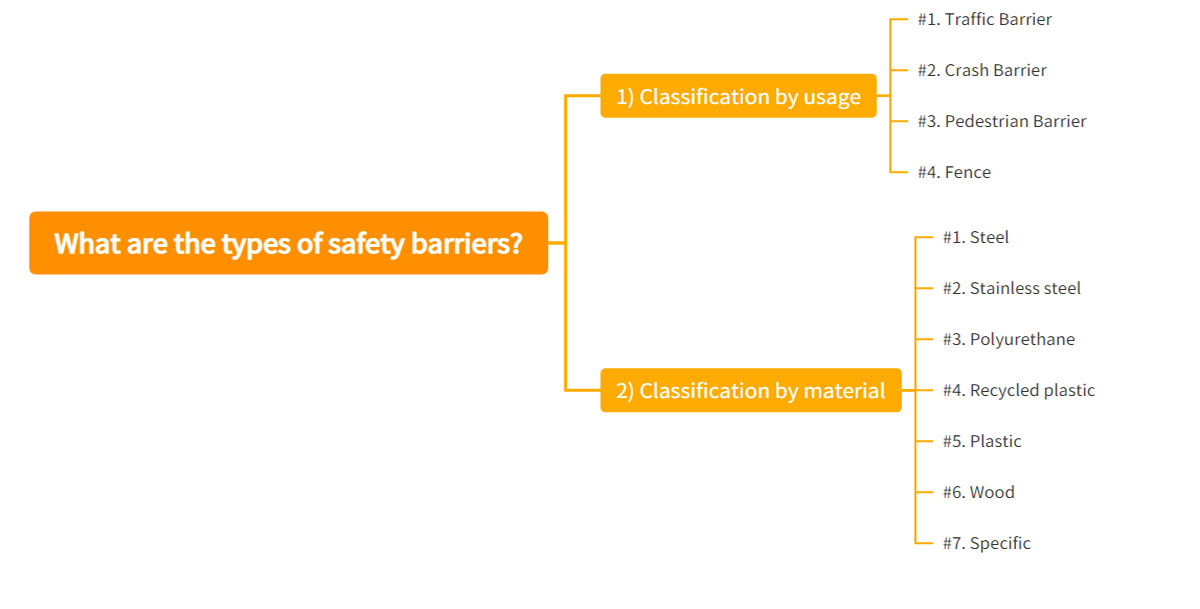

3. What are the types of safety barriers?

This section describes the various types of safety barriers and the different levels of protection they provide. Additionally, you will learn about the various barriers and the types of materials used in their manufacture.

1) Classification by usage

The following is a classification by the use of safety barriers.

#1. Traffic Barrier

Traffic barriers are used to separate traffic lanes and create clear vehicle routes. There are many different types of traffic barriers – from portable temporary barriers to fixed barriers. These can be found inside the facility and on the road.

#2. Crash Barrier

When people refer to “crash barriers,” it’s usually about the guardrails and types of guardrails that line highways and busy roads. Usually made of stainless steel or another type of metal, these guardrails cover long distances and provide serious protection for vagrant vehicles.

#3. Pedestrian Barrier

Pedestrian barriers are the types of barriers that typically define pedestrian routes and sidewalks through areas of busy facilities and increased vehicular activity. Not only do they protect those walking beside them, but they also provide additional support for pedestrians, often in the form of handrails.

#4. Fence

There is no difference between a guardrail and a safety barrier. Safety barriers are just an umbrella term that includes guardrails along roads.

2) Classification by material

The material, shape, and finish of your barrier will depend on your needs. If you’re looking for something strong and safe, you may want to focus on the materials you’ll need, or want something that looks great in your space, you can start your search with the different finishes we offer.

The guide below will provide you with barriers categorized by material.

#1. Steel

- Key Features: Durable, Corrosion Resistant, Chip and Abrasion Resistant, Customizable

#2. Stainless steel

- Main features: high corrosion resistance, pollution resistance, 100% recyclable, easy to clean

In addition to being environmentally friendly and low maintenance, stainless steel barriers are made from 99% recycled waste. Fixing options and sizes range from small to large.

#3. Polyurethane

- Key Features: Corrosion Resistant, High Abrasion and Debris Resistant, Durable, Freeze Free, Extremely Versatile

Barriers made of polyurethane can be cast into various complex shapes. Unlike aluminum barriers, polyurethane barriers do not ice up and can be used to replace degraded ones without affecting your landscaping’s aesthetics. Polyurethane barriers are in A variety of sizes and fixing options are available…

#4. Recycled plastic

- Key Features: Durable, Long Lifespan, 100% Recyclable, Low Maintenance

Recycled plastic barriers are produced using plastic waste and can be inserted with a steel core upon request. Because its non-porous material makes it resistant to rot, algae, or fungal growth, recycled plastic barriers are ideal for demarcating areas in wet or humid conditions. These barriers have a longer product life as they are less prone to degradation over time.

#5. Plastic

- Key Features: Durable, Chemical Resistant, Low Maintenance, Recyclable

Plastic barriers are not only durable and versatile but also offer excellent resistance to impact, breaking, and chipping. Barriers made of plastic are uniquely resistant to most acids, salts, and solvents, as well as environmental elements such as acid rain, soot, diesel fumes, salt, and seawater.

#6. Wood

- Main features: beautiful, corrosion-resistant

We manufacture our timber barriers from Opepe, a strong, stable structural hardwood that is very durable and rot-resistant. These barriers are perfect for natural landscapes, whether it’s a park, woodland, or garden. Timber barriers come with 3 types of fixings: root fixed, lifting and lockable, and base plate.

#7. Specific

- Features: Cost-effective, durable, corrosion-resistant, low maintenance

In addition to providing effective perimeter protection, concrete barriers are durable and cost-effective. Available in a variety of designs and finishes, concrete barriers are a simple and aesthetically pleasing solution for any site requiring protection.

Our concrete barriers can be customized to provide road directions such as: “No Entry”, “Keep Left” or “Bicycle Lane”. Alternatively, they can also be customized to house commemorative plaques or corporate branding. These barriers are root-fixed.

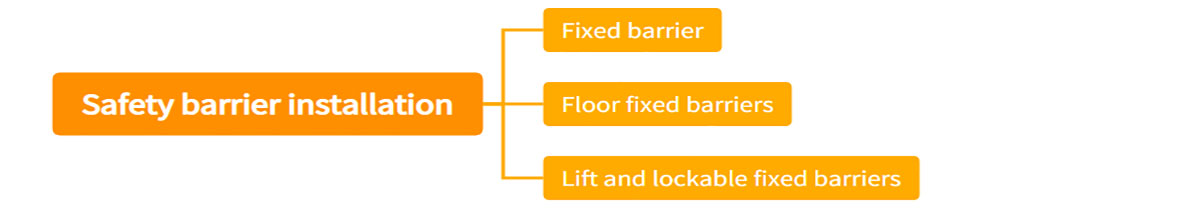

4. Safety barrier installation

Typically, barriers work best when the roots are anchored to a concrete foundation. However, there are exceptions, and we look below at all the different ways to install barriers.

- Fixed barrier

A specially designed section of the barrier is placed in the ground and secured with concrete. This is the safest way to install barriers. Anti-Ram barriers are placed deeper in the ground for added strength and support.

- Floor fixed barriers

Use when the subsurface may be vulnerable or weak, or when drilling down is not possible. A plate was added to the bottom of the barrier design and secured to the concrete surface using a suitable bolting system according to the manufacturer’s instructions.

- Lift and lockable fixed barriers

It is ideal for applications where barriers need to be replaced or removed from time to time.

5. Safety barriers FAQs

Now, that you have known more about safety barriers and the types available, it’s useful to understand what they prevent and what can cause barriers to fail. The following are answers to safety barriers FAQs.

1) What can a safety barrier prevent?

Safety barriers in industrial workplaces are designed to withstand impacts from:

- Car

- Truck

- Forklift

- Pallet jack

- Other on-site vehicles

Safety barriers are designed to protect vulnerable objects from the unexpected impact of moving vehicles, but the amount of force a safety barrier can withstand varies by barrier type.

2) How do you calculate the strength of a safety barrier?

Most safety barrier manufacturers will provide an impact rating for their safety barriers. The rating is a number in joules. When testing safety barriers, this number is derived by multiplying the vehicle’s speed by its weight, taking into account the angle at which it hits the barrier. These ratings provide guidance on how much force a safety barrier can withstand.

3) What can cause a safety barrier to fail?

If the object changes speed or weight, this will affect how successful the safety barrier is at deflecting the impact. If the safety barrier weighs no more than 4.4 tons and does not travel faster than 5 mph, it may be able to withstand the force of a forklift. However, if the driver increases the speed of the vehicle, or if there is additional weight on the vehicle, it may cause the safety barrier to fail.

It is therefore important to observe strict regulations regarding vehicle speed and maximum weight on site. This will ensure that the safety barrier can perform to its optimum specification.

For safety barriers to provide effective protection, you must understand what they protect against. Each Aotons product has been rigorously tested for impact, you can contact our team to know more specifications.

4) What are the Key Safety Barrier Standards and Regulations?

When investing in a security system, it is important to understand what standards and regulations are in place to help you invest in an effective product from a vendor you can trust.

PAS 13 is a code of practice for the installation and testing of safety barriers. It was created by the British Standards Institution in partnership with the blue-chip company steering group and health and safety executives.

As well as standardizing guidelines for safety barrier testing, it is intended to help people configure safety barriers correctly in the field. As long as PAS 13-compliant products meet specific criteria, their impact ratings can be trusted. Your workers, machines, and infrastructure will be protected from unwanted impacts with Aotons safety barriers and bollards.

5) How do concrete, steel, and plastic safety barriers differ?

Although concrete, steel, and plastic safety barriers serve the same basic purpose, the level and type of protection they provide can vary with each material.

- Concrete Safety Barrier

In some cases, concrete barriers can be cast in place or installed at specific locations. Cement is used to attach them to the floor. In order to provide greater impact protection, concrete barriers are sometimes reinforced with steel or metal.

- Steel Safety Barriers

Safety barriers made of galvanized steel are very common – especially on roadsides. These usually take the form of long barriers that separate traffic and prevent vehicles from going in different directions.

- Plastic and Polymer Barriers

Plastic safety barriers are often referred to as “polymer safety barriers,” which refer to the type of material from which they are made. Some polymer barriers are used as temporary protection, while others are stronger and designed for long-term industrial protection. These polymer safety barriers are designed to withstand impacts and then return to their original shape so they can be used again.

Polymer barriers from Aotons offer long-term protection and don’t require maintenance if you need a strong, reliable, and cost-effective safety barrier. Learn more about our security solutions by contacting our team.

6. Conclusion

This article has provided you with an overview of the basic elements that make up a safety barrier and the different types of industrial barriers available.

At Aotons, we provide you with a range of safety barriers, whether you require warehouse protection, efficient traffic management, pedestrian isolation support,t or heavy-duty protection of machinery and structures. Call +0532-86958235 to contact our sales team, please email info@aotons.com to find out what we can do for you.

Leave A Comment