Installed around building columns, column protection are industrial guard that minimizes the impact of motor vehicles or forklifts. They are most commonly found in aisles or areas of warehouses, distribution centers, or manufacturing plants where vehicles pass through, so there is an increased risk of a column (or pillar) being struck. Protectors not only make the column more visible to the vehicle operator, but they also absorb impact and reduce the risk of severe damage to the column leading to structural collapse.

In the previous article, we talked about the definition and benefits of column protection. So in this guide, we’ll focus on the types of column protection and how to pick one. Read on to learn more.

1. Types of column protection

You shouldn’t just buy a post protector just because you have something to install. You need to fully understand the types of column protection to choose them correctly.

1) Divide according to size

- Width: Select a width that matches the amount of space available, the type of column protection material required, and the width of the vertical space you want to protect.

- Height: Post protectors are available in customizable sizes, but standard sizes are 12 inches to 12 feet, and some can be stacked to provide additional height coverage.

- Shape: Some post protectors have a molded shape with a cutout in the center to fit tightly against I-shaped, square, and round verticals. Most are cylindrical to create an equal barrier around the column, but some are cubic or hexagonal.

- Number of pieces: Most post protectors are usually two-piece units that are fixed vertically. However, some post protectors are single-piece, flexible units that wrap vertically.

2) Divide according to color

- Yellow (most common color)

- lime green

- orange

- Multicolor (usually with black and bright stripes)

- Reflective (often added to solid colors)

3) Divide according to materials

Columns are found in most buildings and serve a variety of functions and forms. Each type of column has different requirements when it comes to protection. Fortunately, there are several types of column protection available to meet these needs. Some of the most famous types are made of:

#1. Bubbles

Foam post protectors are one of the most commonly used non-industrial protectors. They come in a variety of colors and densities, making them a fairly diverse choice. Foam post protectors are ideal for coating household or commercial posts and are ideal for childproofing. Foam protectors are often used in car parks to protect against minor impacts, such as those caused by car doors.

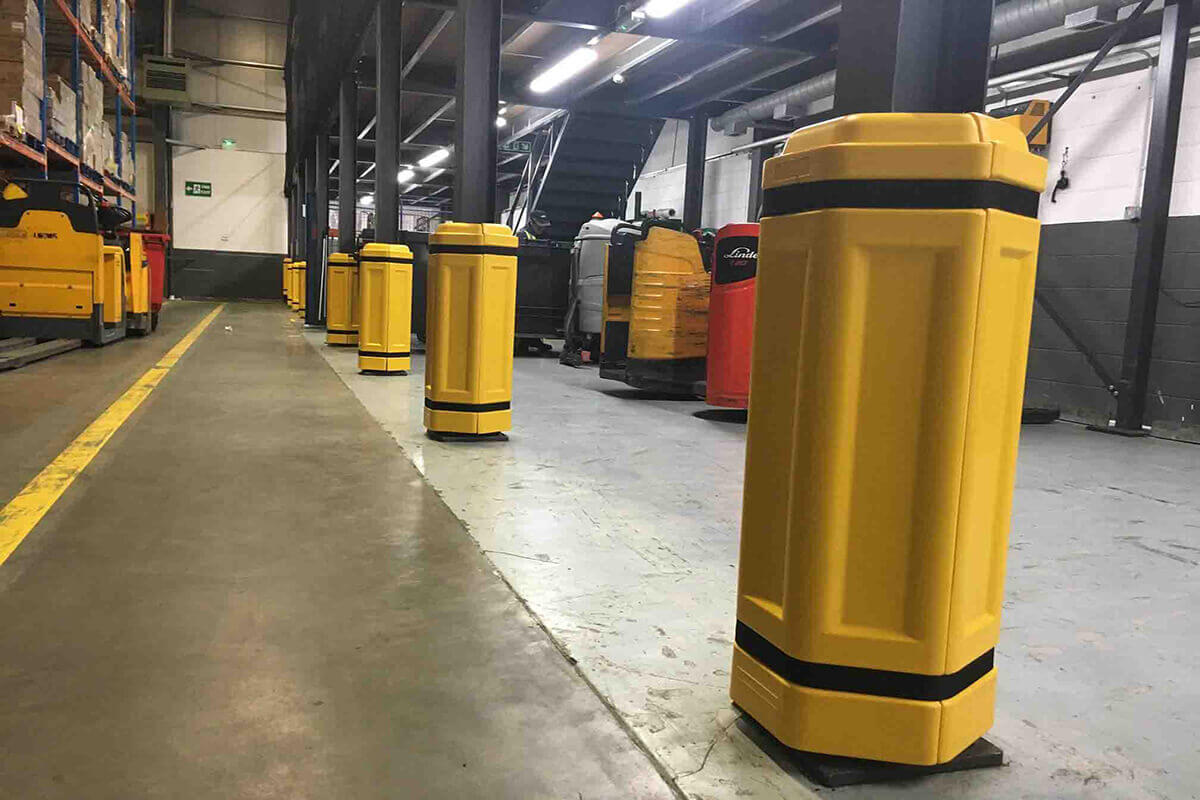

#2. Polyethylene

Polyethylene is a common plastic material that has a variety of uses. Protectors made of polyethylene have an air cushion between the post and its outer wall to absorb any impact. It is commonly used on industrial columns and is ideal for preventing structural damage. This is achieved by using high-density plastic and air gaps to minimize impact damage to the column. The crashing vehicle is thus protected. Polyethylene protectors tend to be thicker than other types of protectors.

To further improve stability, polymer wraparound padded post protectors are often designed to be filled with sand or water for added weight.

Typically, wraparound pillar protectors are colored safety yellow or orange to make them highly visible to vehicle operators. However, because they are made of polymer or plastic, they are easily damaged by vehicle collisions, especially the forks on forklifts. When installed around an I-beam column, there may be a gap between the column protection and two of the four sides of the column if it is not specifically molded to match the profile. Such an opening could easily be used as a trash receptacle.

Additionally, since these protectors are solid walls with no gaps or openings in their construction, they can hide any damage that may exist or occur on the columns. For all of these reasons, this type of post protector is most often recommended for use in areas where vehicle traffic is infrequent or speeds are low.

#3. Metal

There are several types of alloys used for column protection, the most common of which is steel. Steel protectors feature heavy-duty strength and bolting systems to withstand impacts. Although they are heavier than some other types of column protection materials, they tend to be thinner in overall diameter and take up less space around the column. Metal materials are great at preventing structural damage and are very strong. If properly maintained, metal post protectors can last a long time. Some types are even weatherproof, depending on the material.

While steel cage protectors offer a higher degree of protection than polymer-wrapped protectors, they often come with gaps to reduce overall weight. These gaps make it easy to visually assess the condition of the column itself because they do not obscure it. Instead, depending on the size of the gap, the forks may go around the frame and hit the uprights through the opening.

Additionally, while they are more resistant to impacts, their rigid nature makes them susceptible to damage or even the anchor falling off. Steel cage post protectors are generally ideal for areas where medium to heavy vehicles travel at low to moderate speeds. They are also ideal for columns serving as structural supports, whether for mezzanines or elevated work areas, or those that are integral to the integrity of the facility.

#4. Vinyl

Vinyl post protectors may be less effective at preventing structural damage than other types. However, they are well protected against surface damage such as bumps and scratches. Because vinyl protective films are so aesthetically pleasing, they are often used in homes or commercial settings. This protective material is commonly used in car dealerships and shopping malls to protect light poles from minor impacts.

#5. Eraser

Rubber post protectors are among the most cost-effective post protectors on the market. They also come in a variety of densities, each suited to a specific function. The lower density is ideal for use as column sleeves to protect against bumps and scratches. High-density rubber post protectors, on the other hand, are great at absorbing impacts. Due to their versatility, rubber post protectors can be used in commercial, domestic, and industrial settings.

Rubber posts are more susceptible to wear and tear than other types of post protectors. However, the cost and ease of installation more than make up for this. They are also very weather-resistant, which is a plus. Additionally, rubber posts are very easy to clean, and proper cleaning can extend their lifespan.

#6. Mix

Many column protection uses a mixture of materials. By mixing, individual column protection can take advantage of the advantages offered by each material type. For example, foam-coated polyethylene protectors provide excellent shock absorption. Foam coating helps protect plastic materials from breakage. Rubber-coated hard materials, on the other hand, increase weather resistance while maintaining protective benefits.

Their hybrid design combines the strength of steel with the flexibility of polymer, allowing them to provide a higher level of impact protection. However, while hybrid post protectors are offset from the posts (making it easier to see any damage that may be present or occurred), they also have gaps that can be penetrated by forks.

Additionally, they are also typically the most expensive option due to their multi-material construction. Therefore, they are most commonly recommended for use in areas and aisles with heavy traffic, and high speeds, or for structural support columns supporting mezzanines, elevated work platforms, or critical building elements.

4) Divide according to fixed method

- Velcro straps: Velcro straps, usually made of nylon, are wrapped around the post protector to secure it to the surface. Velcro straps are easy to install and maintain. They are available in a variety of colors, including a reflective finish.

- Bolts: Bolts hold the various parts of the post protector together and also secure it to the ground.

- Snaps: Snaps use four rivets to attach to the post protector that locks to the upright post.

- Zip Ties: Ties are wrapped around the post protector to hold them in place.

- Reflective Tape: Reflective tape wraps the lightweight post protector in place. They come in many colors.

2. How do I select the appropriate column protection for my facility?

Choosing the right column protection for your facility is an important decision that affects the safety of your employees and visitors as well as the longevity of your building. A few key factors to consider are as follows:

1) Assess your facility’s needs

The first step in choosing the right column protection is to evaluate your facility’s needs. Consider the traffic flow at your facility and the types of vehicles and equipment available. Are there areas with a higher risk of impact, such as loading docks or parking lots? The answers to these questions can help you determine the level of protection required for your column.

2) Choose the right material and size

Once you’ve assessed your facility’s needs, you can begin to narrow down your material and size choices. Steel protectors offer the highest level of protection, but may be overkill for low-risk areas. Plastic protectors are a cost-effective option that still provides good protection, while foam protectors are ideal for low-impact areas.

When choosing a size, be sure to measure the diameter and height of the column to ensure a good fit. Most column protection is available in a variety of sizes to accommodate different column types.

3) Aesthetics

Post protectors come in a variety of shapes, colors, sizes, and designs. If you are purchasing a protector for residential or commercial use, you should consider the overall aesthetics. After all, there is no reason to buy a design that doesn’t match your interior decor.

On the other hand, in an industrial environment, aesthetics are not that important. However, if you can get a protective device for your industrial building that is both practical and stylish, then why not? Some would consider using brighter colors to help develop on-site occupational health and safety standards and policies.

4) Material

The most critical choice you have to make is the material that makes up the protector you purchase. This material directly affects the function of the column protection. For example, some materials have excellent weatherproofing properties. Others provide better protection against structural damage.

5) Budget

Some types of column protection are more expensive than others. You need to consider your budget and make trade-offs based on the features you need. For example, there is no point in buying a top-of-the-line column protection for its simple anti-scratch feature. Be sure to consider these things carefully to avoid unnecessary expenses.

6) Installation precautions

Installation is another important factor to consider. Others can be installed by your own staff, while others require professional installation. Be sure to read the installation instructions carefully and consider any additional equipment or tools you may need.

7) Compatibility with other security devices

Finally, consider whether your post protectors need to be compatible with other safety equipment, such as bollards or guardrails. Some are designed to be used with other safety equipment, while others may need to be installed separately. By considering these factors and choosing the right column protection for your facility, you can ensure the safety of your employees and visitors, protect your building’s columns from damage, and ultimately save your facility time and money in the long run.

The bottom line is don’t buy a post protector just because it looks good. What matters more is functionality, so be sure to consider the factors we mentioned above. There is a great deal of importance placed on materials, in particular.

3. How much does a column protection cost?

- Post protectors range in price from $15 to over $1,000 each, depending on the type, as mentioned earlier in this article.

- Column protection with non-standard options is more expensive because it requires special customization.

4. Conclusion

That’s our summary of things to consider when purchasing column protection. After reading this article, I believe you can find the column protection you want. If you would like more information on column protection pricing, please contact Aotons for a consultation.

Leave A Comment