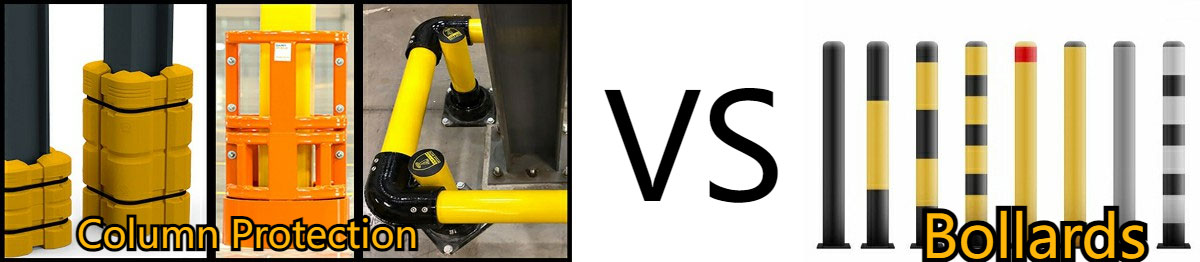

When working in a limited facility, unplanned expenses for machinery and equipment are often caused by impact damage. However, costly repairs, production downtime, and even new purchases can be easily avoided! With the right impact and collision protection, you can effectively protect your inventory from impact. At the same time, you can minimize the risk of workplace accidents. Impact and collision protection can be achieved by installing column protections and bollards, so how do you choose between the two?

In today’s guide, we’ll compare these two protectors. More specifically, we compared two types of post protectors made primarily of steel and/or plastic and evaluated their durability and efficiency.

1. About column protection

These guards surround a building’s columns like a fence and are sometimes called “column guards” or “column bumpers.” They usually surround the column continuously on all sides. The plastic wraps around the pillars, just like a car bumper – if you hit the bumper, the car will feel the impact. The special column protection made of steel does not come into contact with the column. Because they are bolted directly to the floor, the posts remain intact when they are struck.

2. About bollards

Bollards are usually fixed to the ground. These safety devices can be used in a variety of applications, and protecting building columns is one of them. They also vary widely in materials, design, and installation.

To help you choose the best option, let’s start the comparison now. We will analyze the durability and efficiency of each type of post protector, specialty protector, and bollard.

3. Column Protection VS. Bollards: Durability

Below is a durability comparison between steel column protections, steel bollards, and plastic column protections, plastic bollards.

1) Column protection

Below are steel and plastic column protections.

#1. Steel

Let’s first discuss steel-specific column protections. This type of protector surrounds the building columns and is anchored to the concrete floor. Because the protector remains independent, the impact it receives is not transferred to the building columns.

It’s made from 1/4-inch-thick structural steel that can withstand repeated hard impacts. It is also important to analyze the warranty provided by the manufacturer. A longer warranty is a great indicator of the manufacturer’s trust in the durability of their product, while also giving you peace of mind.

For example, it comes with a 2-year manufacturer’s warranty. This means that it is guaranteed to be free from defects in material and workmanship during this period. As we will see, this is much longer than common warranties for other types of protection.

#2. Plastic

Plastic column sheathing is similar in shape to steel sheathing. However, the fact that they are made of plastic rather than steel tends to reduce their durability. For example, they are more likely to be punctured by the forks of a forklift. If we turn to warranties, we see that warranty periods vary widely between manufacturers, but 90 days or less is not uncommon, which pales in comparison to the 10-year warranty mentioned earlier.

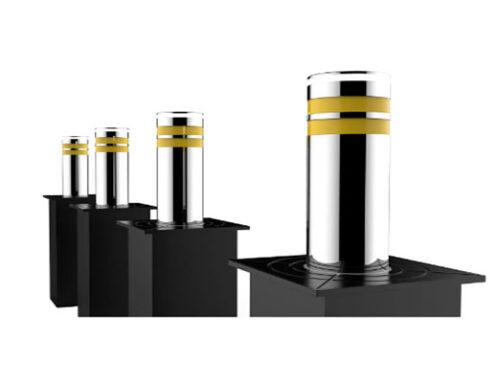

2) Bollards

Below are steel and plastic bollards.

#1. Steel

Generally speaking, fixed bollards are more durable than retractable bollards. For protection purposes, it is best to use steel bollards embedded in concrete as they offer greater durability than other types of bollards. Like steel specialty column protections, they are independent of the structure they protect. Warranties also vary widely between different types of bollards, but warranties ranging from 1 to 5 years are common. Additionally, unlike most specialized column protections, bollards do not provide wraparound protection, leaving a partially unprotected area around the building’s columns.

#2. Plastic

Plastic bollards are mainly used for their flexible qualities. In many cases, they are designed to provide indications about circulation in a specific area, such as controlling access to a park, warehouse, or a certain part of a street. They are easy to use, relatively cheap, and often removable and reusable, which makes them a good and durable option in certain situations.

Key Takeaway: Durability

|

Column protection |

|

| Advantage | Shortcoming |

|

|

|

Bollard |

|

| Advantage | Shortcoming |

|

|

4. Column Protection VS. Bollards: Efficiency

Below is a comparison of the efficiency between steel column protections, steel bollards, and plastic column protections, plastic bollards.

1) Column protection

Below are steel and plastic column protections.

#1. Steel

When it comes to the effectiveness of protectors around steel posts, it really depends on the manufacturer. If we take the example of the Dharma Shield again, its efficiency depends on strategic key elements, such as the fact that it is anchored directly to the ground. This property makes it particularly efficient because it is completely independent of the column. Therefore, when the Dharma Shield is hit, the pillar remains unchanged.

Available in a variety of standard sizes to fit the most common constructions. The protector can also be customized into other shapes for optimal protection. This may be useful if the building structure also houses other equipment that needs to be accessible, such as pipes or fire extinguishers. Steel extensions are also available if required.

Regardless of their shape, the fact that they usually surround the column continuously from all sides makes them an effective choice because they can protect a large area of the column. The ease of installation should also be considered.

#2. Plastic

Plastic protectors also come in a variety of shapes and sizes and fit most standard building columns. These protectors typically do not offer customization options and typically do not deviate from standard available sizes. However, some can be safely covered in a variety of sizes to accommodate different building column sizes.

When it comes to impact protection, plastic protectors are often wrapped around uprights and rely on them for support: they are not anchored to the ground. As a result, the force of the impact is transferred to the structure supporting the protector, potentially causing serious damage.

The advantages of plastic protectors are ease of installation or removal and price. Because these devices are typically secured with bolts, clamps, or straps and are not typically anchored to the ground, installation takes only minutes to complete and requires few tools. If operations such as maintenance or cleaning are required on the building columns, the same goes for the demolition process. As for price, they tend to be less expensive than steel column protection, usually between $200 and $600.

2) Bollards

Below are steel and plastic bollards.

#1. Steel

As for bollards, due to their relatively small size, they can be placed almost anywhere in the warehouse. They can also focus protection on individual areas of a building structure. For example, if only 1 corner of a column is exposed to heavy forklift activity, installing bollards may be a better solution than surrounding the entire column with protection. The type of bollard installed can also affect its efficiency.

Embedding a bollard in concrete requires more time and effort than anchoring it to the ground – although it increases the bollard’s sturdiness. As you can imagine, the removal process can vary as well. Either way, both processes require additional tools. Additionally, since bollards are installed only a few centimeters from other bollards, the gaps between the posts leave certain areas of the posts unprotected.

#2. Plastic

As mentioned before, plastic bollards are mainly used in public places to control pedestrian circulation in a specific area. Because they are easy to use, relatively cheap, and often removable, they are an effective option in situations that do not involve repeated impacts with the vehicle.

Key Takeaway: Efficiency

|

Column protection |

|

| Advantage | Shortcoming |

|

|

|

Bollard |

|

| Advantage | Shortcoming |

|

|

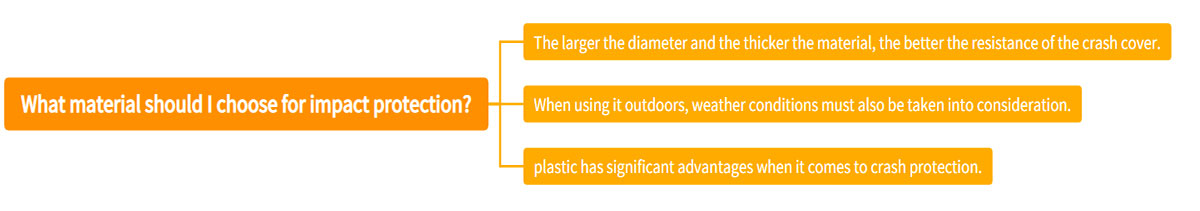

5. What material should I choose for impact protection?

Both column protections and bollards protect your product as well as your site. When choosing a material, you should ask yourself what impact protection must do. There may be a need for different material properties depending on the application. Generally speaking, the larger the diameter and the thicker the material, the better the resistance of the crash cover. If your company uses heavy and fast machines, you should use exceptionally stable crash protection.

When using it outdoors, weather conditions must also be taken into consideration. If you need an especially strong impact protection system, you should choose hot-dip galvanized steel products that can prevent rust damage. In contrast, plastic crash guards are completely corrosion-resistant – there’s no reason to worry about rust damage, even after a collision with a vehicle. However, galvanized steel is generally a better choice for outdoor use because plastic products have poor UV resistance. However, plastic has significant advantages when it comes to crash protection, as the rounded shape and elastic material reduce impacts and therefore protect approaching devices.

6. Conclusion

That’s how column protections and bollards compare in terms of durability and efficiency. Once you realize the importance of protecting building columns, helpful information about the different options will help you reflect on your specific needs: You will then be able to make the best decision for your building. Protecting the structural integrity of your building will help ensure day-to-day operations run more smoothly. Ultimately, it will make it easier for you to keep your employees, your products, and your buildings safe!

Leave A Comment