Hydraulic Bollard

Aotons Hydraulic Bollard is an anti-collision safety product with high blocking ability. The automatic bollards are driven by the internal hydraulic bollard system.

When the motor vehicle needs to be controlled or intercepted, it can be controlled to rise above the ground by remote control and other means. When it reaches the blocking height, it will automatically stop, playing the role of control and interception; When the motor vehicle is allowed to pass, it will be automatically recovered to the level position of the road surface;

Its buried installation method will not damage the overall style of the building complex, and it is widely used in oil depots, banks, troops, power stations, and other places for control and anti-terrorism interception.

Aotons Hydraulic Bollard Features

Aotons hydraulic bollard integrates a hydraulic system, and the power unit and lifting system are designed as a whole, with stable performance.

Advanced anti-corrosion design: The protection grade of the hydraulic system is IP68, the lifting column is made of 304 stainless steel, and the oil cylinder push rod is treated by nitriding process, which improves its wear resistance and corrosion resistance.

High strength blocking performance: The automatic hydraulic lifting columns have outstanding blocking performance, they can block the impact energy of 1108kj, which is equivalent to blocking the frontal impact of a 6.8-ton vehicle at the speed of 65km/h, stopping the driving of the vehicle, and the lifting column can still be lifted and used normally.

Easy maintenance: The modular design is adopted inside the lifting column. During maintenance, it only needs to remove the screws and replace the accessories, which avoids the problem of repairing the traditional lifting column which needs to be dug out of the ground and re-installed, and reduces the maintenance difficulty and cost.

Hydraulic Bollard Tech Data

| Model: | CA-W-C89 |

| Size: | 1.5mx0.8m |

| Steel Pipe Diameter: | 89mm |

| Steel Pipe Thickness: | 3mm |

| Deflection Angle Limit: | 20° |

| Alarm mode: | Sound alarm |

| Alert setting: | LED light alert |

| Structure: | Split design |

| Material: | black cast iron base + galvanized steel pipe +Yellow reflective sticker + Anti-collision rubber ring |

| Explosion-proof grade: | Ex ia IIB T4 Ga |

Hydraulic Bollard System

The internal hydraulic bollard system drives the bollards with its different features

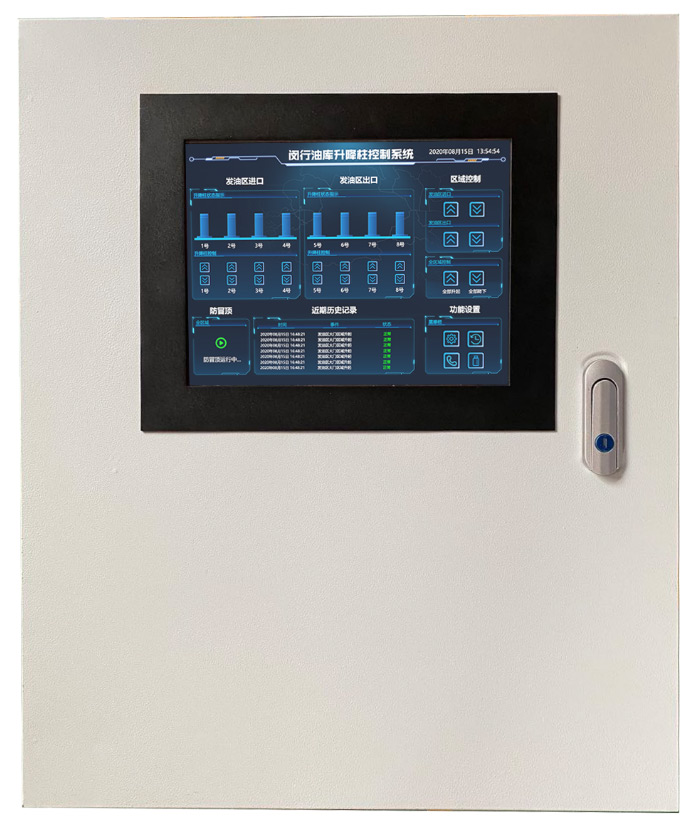

LCD Display: The 12-inch LCD equipped with the hydraulic bollard system can display the status information of the hydraulic bollard in real time. When there is a fault, it will display the alarm information in real-time and send a voice alarm to remind the staff to check the cause of the failure as soon as possible to reduce unnecessary losses.

Remote communication: The hydraulic bollard system has the function of remote communication. The control system is equipped with a communication network port. After inserting the physical network cable, the IP information can be set correctly to access the local area network, so that it can communicate with any equipment that supports network communication, which is convenient to access the equipment integration platform.

Historic records: The hydraulic bollard system can automatically record the system work records, such as operation records, alarm records, and data upload records. The operation records can be saved for up to 5 years, which is convenient for users to query. It is equipped with a USB interface, which can export the saved history records to the U disk with one click.

Free definition: The hydraulic bollard system can customize the display information on the 12-inch LCD, including system name, partition name, system time, etc. The intelligent control program of the system can bring more operation possibilities to the user.

Hydraulic Bollard System Tech Data

| LCD | 12 inch LCD screen |

| Supply voltage | 220VAC 50Hz |

| Working temperature | -20℃~70℃ |

| Alarm mode | Display alarm, audible alarm |

| Degree of protection | IP54 |

| Limit detection | Real-time detection of whether the lifting column is lifted in place |

| Communication interface | 485, Switch signal, network interface, USB |

| Control method | Manual, remote control, touchscreen operation, linkage control |

| Other functions | Automatic pressure compensation, free group control, history record, overcurrent protection, electricity leakage protection |

| Control quantity | 1-8 PCs, customizable |

| Overall dimension | 500mm*600mm*200mm, customizable |

Steps to Custom Hydraulic Bollard

Order Review & Confirmation

Upon receiving an order, we carefully review it to ensure that we fully understand the customer’s requirements. We then confirm the order with the customer and send a confirmation letter.

We have a team of experienced engineers who are responsible for the overall hydraulic bollard solution and design. This ensures that the required specifications are met and customized according to the customer’s needs.

We design and manufacture hydraulic bollard in-house using state-of-the-art equipment and skilled technicians, and we carry out quality control checks during the production process to ensure the delivery of high-quality custom hydraulic bollard.

We provide transportation and installation services to ensure that hydraulic bollard are installed correctly and safely. We provide documentation and technical support to assist customers through the installation process.

After-sales Support

We offer our customers after-sales support with a 2-year warranty, including a free warranty for collision damage, and instructions on how to operate and install hydraulic bollard.

Hydraulic Bollard After-Sales Service

2 Years Warranty

All the safety barriers of Aotons are supported by 2 years warranty. Besides, the damage caused by the collision of the vehicle, our company promises a free warranty.

Easy to Install

An installation process video is provided. The product is fully modular in design, easy to assemble and does not require special tools.

Free Install Tools

Some products provide free installation tools, and you only need to equip a commonly used impact drill, wrench and screwdriver to complete the installation.

Customized Color Support

After reaching the minimum order quantity, the product can be customized in color. We provide standard warning colors and universal color codes for you to choose from.

Customized Service

Parameters such as product length and height can be customized, and beam spacing can be customized based on parameters such as impact height.

Distributor Support

Provide remote video guidance for installation, or after passing the training, you can also apply to become our certified installation service provider.